-

- Solutions

- Accessories & Parts

- Controls

- Safety

- Lifts & Specialty

- Seals & Shelters

- Vehicle Restraints

- Dock Levelers

Solutions

NORDOCK® designs and manufactures innovative solutions for highly specialized applications and unique environments. Discover our industry best solutions that will ensure your loading dock is safer and reduces operating costs by improving productivity.

-

Cold Storage

& Food GradeComprehensive solutions to conserve energy and lower costs.

-

End Loading Trailers

Solutions that eliminate damage to goods and speed up unloading.

-

Power Outages

Keep your docks operable in an outage to avoid costly downtime.

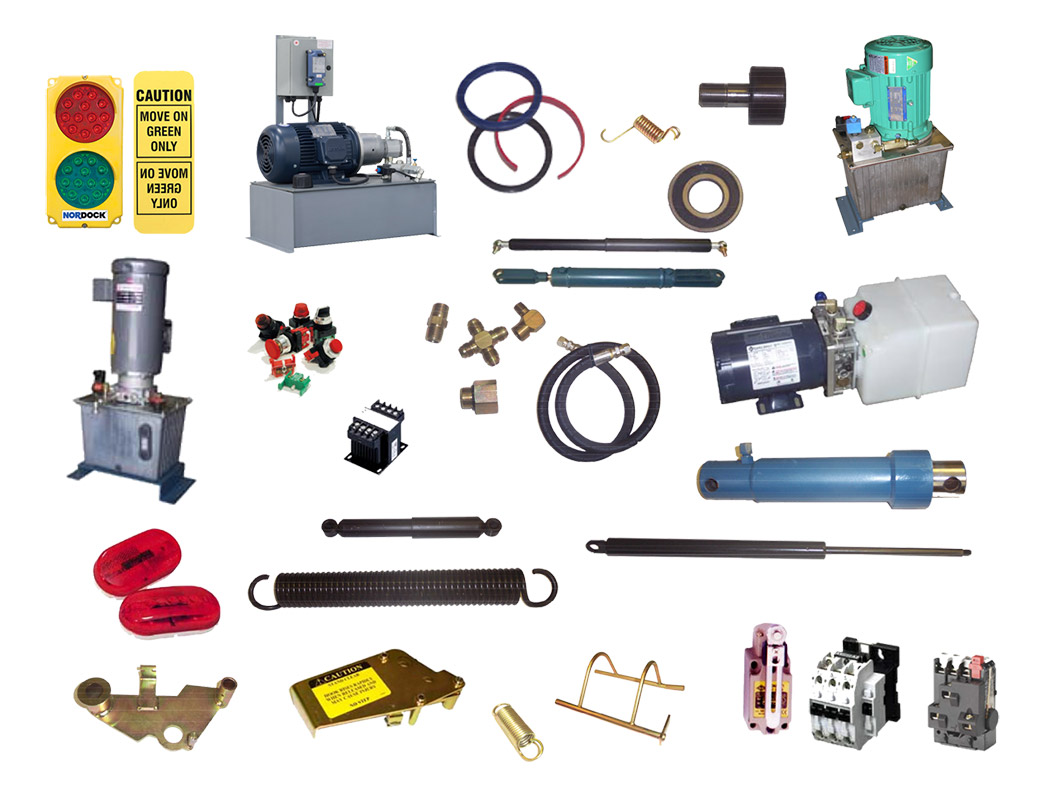

Accessories & Parts

For all the accessories and parts you need, all under one roof, all you need is NORDOCK®.

-

REPLACEMENT PARTS

NORDOCK® stocks hundreds of common replacement parts and repair kits for dock levelers, restraints, and scissor lifts.

-

ALL-SEAL™

Ultimate solution in energy efficiency, it provides a superior seal throughout the levelers full operation range.

-

SUPER-COM™

LED lights maximize safety with visual communications at the dock site.

-

HYDRAULIC CONVERSION KIT

This kit enables you to have the benefits of a hydraulic dock leveler and will reduce maintenance costs and down time.

-

LOADING DOCK LIGHTS

Energy efficent and environmental safety, these LEDs light up the trailer bed and dock to your satisfaction.

-

IMPACT BUMPERS™

Protection for your building, dock leveler, dock seal, and restraint from damage.

Control Panels

With a wide range of control panel configurations available, NORDOCK® can meet your precise needs and create that single point of control to simplify your operation, save time and reduce the chance of human error.

-

LOGI-SMART™ CONTROL SYSTEM

Control system will integrate your entire operation to ensure optimum efficiency and safety.

Safety Products

NORDOCK® offers the full line of safety products that will help prevent injuries, damage and create a safe and efficient workplace environment.

-

VEHICLE RESTRAINTS

(HOOK, NON-IMPACT & WHEEL MODELS)Full line-up of premium vehicle restraints delivering superior performance and safety.

-

FALL-SAFE™

(MODEL SBL)The Model SBL's exclusive patented design features a sliding lip to prevent accidental fall-off when stored.

(Capacities of 30,000 to 80,000 Lbs.)

-

BARRIER™

(MODEL NB)The Model NB is equipped with a STAY-PUT™ barrier lip, this leveler prevents accidental fall-off in its stored positions.

(Capacities of 30,000 to 160,000 Lbs.)

-

FALL-STOP™ BARRIER GATE

(MODEL ASG/MSG)The Model ASG/MSG electric and manual barrier gates provide added safety by preventing fall-off at the loading dock.

-

DOK-COM™ LED COMMUNICATION SYSTEM

This system uses precise two-way communication between driver and attendant making your dock site safer.

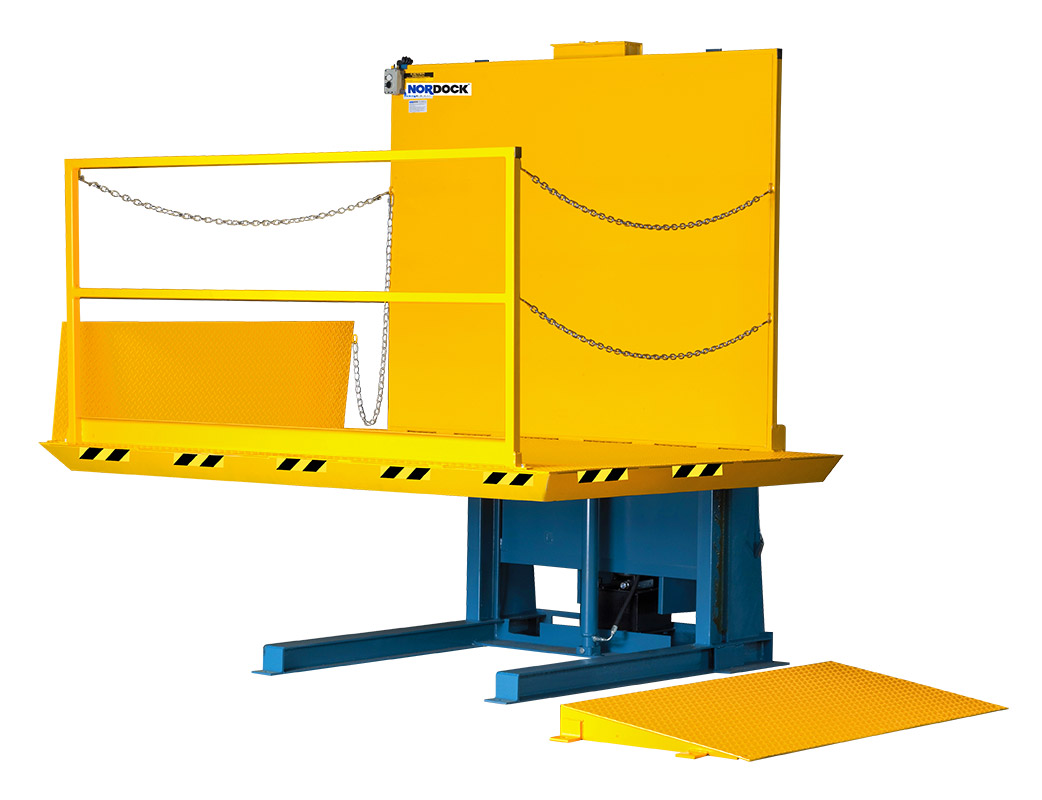

Lifts & Specialty

Whether you need to lift, tilt or rotate 1,000 to 100,000 lbs., turn to the experts at NORDOCK® to find the right solution.

-

DOCK-LIFT™

(MODEL DL)The Model DL is the ultimate scissor lift equipped with full hydraulic powered functions.

(Capacities of 5,000 to 20,000 Lbs.)

-

TRUCK-LIFT™

(MODEL TL)The Model TL lifts all types of trailers to dock height and provides a level loading dock on uneven terrain.

(Capacities up to 60,000 Lbs.)

-

MAST-GUIDE™

(MODEL MG)The Model MG is a platform lift with a low profile and superb stability without pit installation.

(Capacities of 5,000 to 20,000 Lbs.)

-

INVERTERS & UP-ENDERS

(VARIOUS MODELS)Ergonomically designed to rotate products between 90 & 180 degrees.

(Capacities up to 100,000 Lbs.)

-

ERGONOMIC™ PLANT LIFT

(MODEL SL)The Model SL is easily positioned to keep work at a comfortable height, reducing stress and avoiding injury.

(Capacities of 1,000 to 10,000 Lbs.)

-

ERGONOMIC™ TILT PLATFORM

(MODEL TP)The Model TL customizable lift keeps work at a comfortable height and materials within reach.

(Capacity of 10,000 Lbs.)

-

ERGONOMIC™ TURN TABLE

(MODEL TT)The Model TT features a rotating deck that makes material handling fast and easy with reduction of worker fatigue.

(Capacities of 1,000 to 10,000 Lbs.)

-

RAIL-SPAN™ BRIDGE

(MODEL RS)Designed to bridge rail track openings in 20′ spans or greater.

(Capacities of 10,000 to 50,000 Lbs.)

-

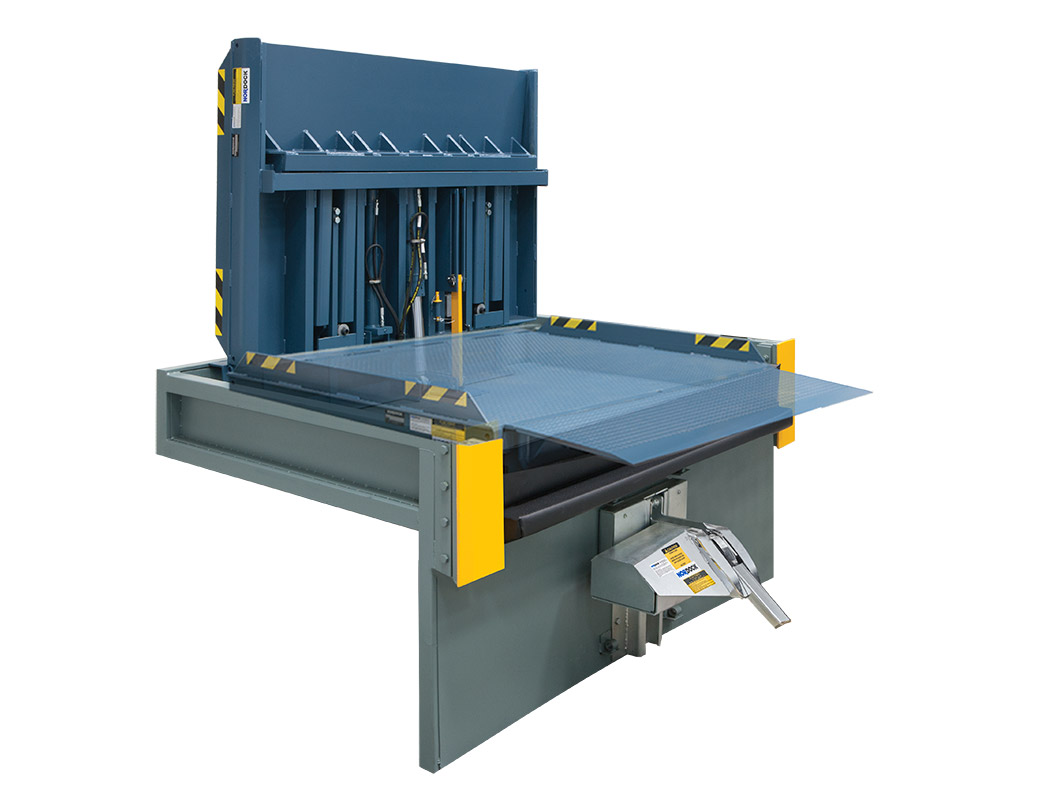

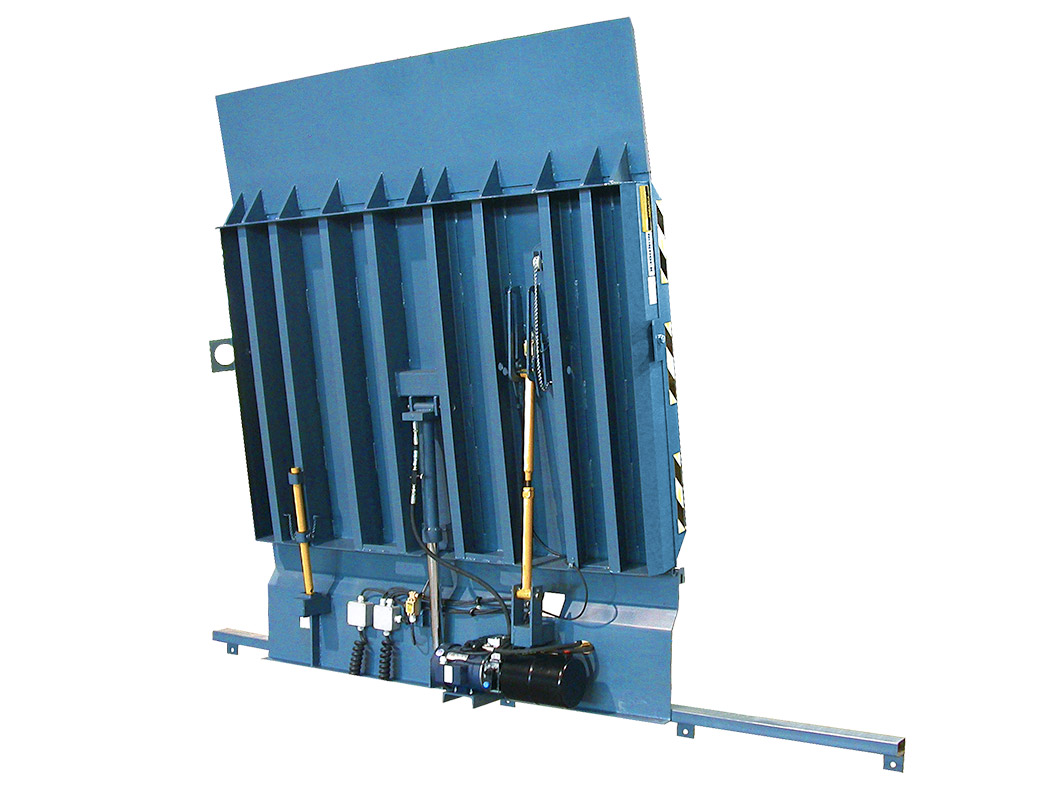

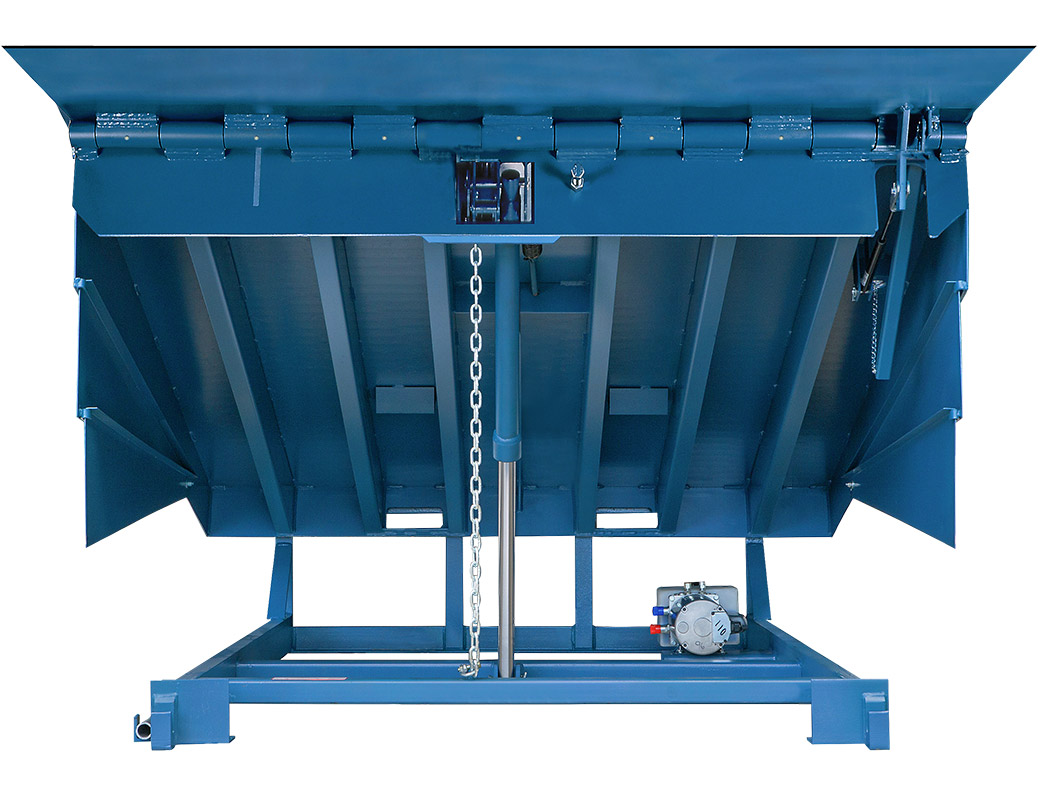

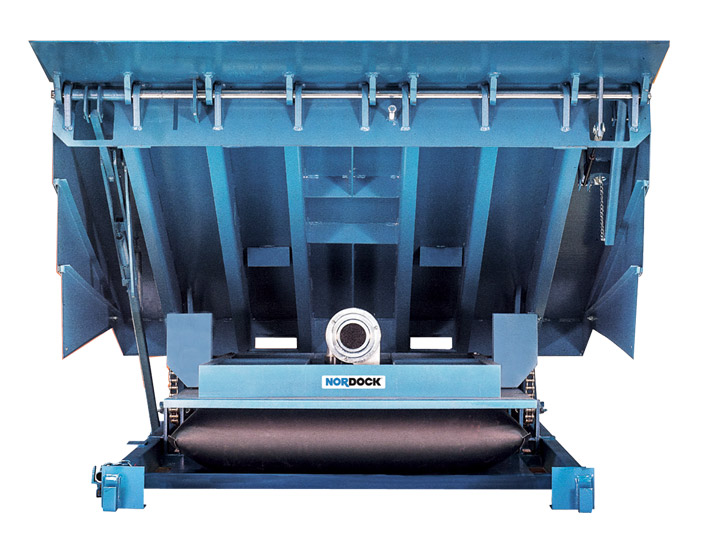

VERTICAL STORING PLATFORM

(MODEL VSP/VSPL)The Model VSP/VSPL is designed to load or unload trucks and trailers where permanent equipment placement is not possible.

(Capacities up to 20,000 Lbs.)

-

HI-LIFT™ SERIES

(VARIOUS MODELS)Exceptional Double & Triple Lift solutions for exceptional situations.

(Capacities of 3,500 to 20,000 Lbs.)

-

CUSTOM LIFTS

(VARIOUS MODELS)Exceptional lifting solutions offering superior features and quality to deliver an unequaled return on investment.

(Capacities of 1,000 to 100,000 Lbs.)

Seals

NORDOCK® offers the industry's highest quality tear and abrasion resistant fabric and ultra-resilient foam creating a superior dock seal reducing energy costs.

-

WEARTOUGH®

CURTAIN STYLE FOAM PAD (MODEL FC)The Model FC velcro-split head curtain is designed to suit a wide variety of truck heights.

-

WEARTOUGH®

STATIONARY HEAD PAD (MODEL FP)The Model FP provides a maximum weather-tight compression style seal.

-

WEARTOUGH® SEAL TITE™

TRAILER DOOR GAP SEAL (MODEL STP)The Model STP closes off the air gap created by swing out trailer doors and is available with a stationery head pad.

-

WEARTOUGH® SEAL TITE™

(MODEL STC)The Model STC is designed to keep contaminants out with gap compression foam and is equipped with a head curtain.

Shelters

Superior in versatility, performance and efficiency, explore the industry's best rigid frame, retractable or inflatable shelters.

-

MIDNIGHT™ FOAMFRAME™

FULL FEATURED (MODEL FF-RS9)The Model FF-RS9 features combined advantages & provides the ultimate light blocking effect.

-

WEARTOUGH®

CURTAIN STYLE (MODEL FL)The Model FL "L" pad & curtain style dock seal adapts to a wide range of trailer widths.

-

WEARTOUGH® FOAMFRAME™

(MODEL FF)The Model FF is a foam sided shelter with superior sealing capability.

-

WEARTOUGH®

(MODEL DS)The Model DS provides maximum dock protection and full access for the greatest range of trailer widths and heights.

Rain Diverters

NORDOCK® Rain Diverters are designed to exceed requirements and customer satisfaction.

-

RAINSHIELD™

TRAILER TOP SEAL (MODEL RS-5000)The Model RS-5000 provides effective dock protection for trucks in a decline approach.

-

RAINSTOP™

TRAILER TOP SEAL (MODEL RS-9000)The patented Model RS-9000 diverts water, wind and contaminants away from the dock area to protect products, personnel and property.

Specialty Shelters

NORDOCK® Specialty Shelters offer superior protection for standard boxcar loading/unloading operations.

-

BOXCAR™

INFLATABLE (MODEL IR-650)The Model IR-650 provides effective protection for personnel and cargo while loading and off loading standard box type railcars.

-

BOXCAR™

INFLATABLE (MODEL IR-700)The patented Model IR-700 is designed to provide the most effective solution to protect personnel and cargo while loading rail cars.

-

WEARTOUGH®

INFLATABLE (MODEL IS-950)The Model IS-950 is the most versatile shelter available. Inflates after the trailer is positioned and seals a wide range of sizes.

-

WEARTOUGH® FOAMFRAME™

COMBINATION (MODEL FFI-750)The Model FFI-750 provides the ultimate protection for personnel and cargo while loading and off loading trailers.

-

WEARTOUGH®

MULTI-SEAL™

(MODEL MS)The patented Model MS is designed to provide a tight dual action seal against both the rear and sides of a truck or trailer.

-

WEARTOUGH® RETRACTAFRAME™

(MODEL RF)The Model RF provides unrestricted access to the back of the trailer during loading operations.

Rotating Hook Impact Style

Engages when impacted by the rear impact guard, these restraints eliminate early departure and trailer creep.

-

SMART-HOOK®

(MODEL AR-10K)The Model AR-10K is a premium automatic vehicle restraint designed to secure trucks at the loading dock by using a large rotating hook.

-

SMART-HOOK®

(MODEL AR-20K)The Model AR-20K offers the most enhanced loading dock safety & performance in the industry, securing all trailers with rear impact guard obstructions.

Non-Impact Style

Vertically operated, these manual & automatic restraints secure virtually all trailers at the loading dock with over 32,000 lbs. of restraining force & 100,000 lbs. of mounting force.

-

TRUCK-LOCK®

(MODEL MTL)MTL Models are manually operated restraint offering security at the loading dock.

-

TRUCK-LOCK®

(MODEL ATL)ATL Models are automatic units that activate and stores the spring-loaded HYDRA-FLOAT™ barrier via push button control.

-

PIT HOOK™

(MODEL PH-3000)The Model PH-3000 is recessed into the dock offering unobstructed and trouble free vehicle engagements.

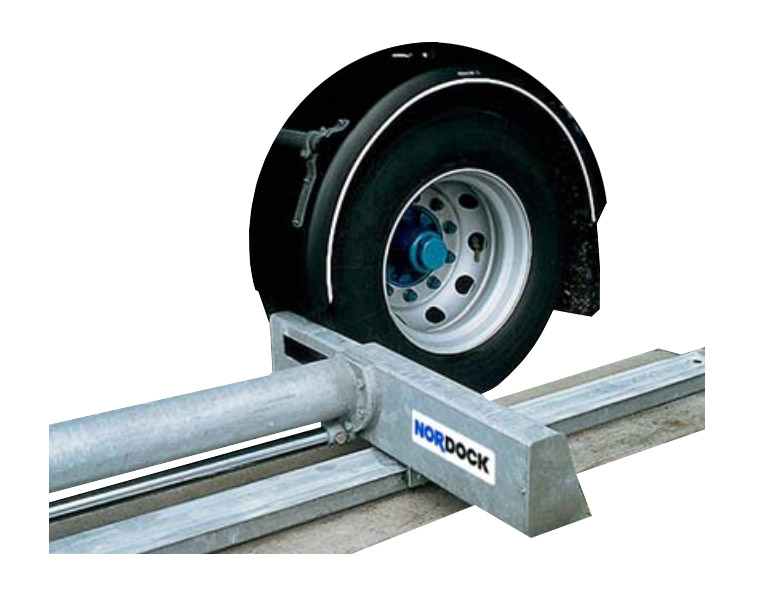

Wheel Restraints

Safely engage one or more wheels of a transportation vehicle, restraining uncontrolled movement of the vehicle.

-

DOK-CHOCK™

(MODEL DC-300)The Model DC-300 prevents movement and provides synchronized interlock capable communication to both truck driver and dock personnel.

-

POSI-CHOCK™

(MODEL PC-6000)The Model PC-6000 is a premium automatic restraint designed to secure a trailer at the loading dock by engaging the wheel with a large steel chock.

-

SHUR-LOK™

(MODEL SL-7000)The Model SL-7000 is an automatic surface mounted hydraulic powered restraint that seeks out and restrains trailer wheels.

Telescoping-Lip

TELESCOPING-LIP™ dock levelers are an innovative and practical solution to common end loading issues in material handling. They are a superior energy efficient alternative to vertical storing levelers allowing the leveler to fully retract so the insulated dock doors can store against the pit floor.

-

TELESCOPING-LIP™

(MODEL NVTL)The Model NVTL’s patented design eliminates end load interference issues forever and provides superior sealing.

(Capacities of 30,000 to 50,000 Lbs.)

-

TELESCOPING-LIP™

(MODEL TLH)The Model TLH provides an effective alternative to vertical storing dock levelers, solves end loading issues and offers a complete seal at the door.

(Capacities of 30,000 to 100,000 Lbs.)

-

RETROFIT™

(MODEL TLHR)The RETROFIT™ Model TLHR is the best available solution for under performing docks & replacing existing dock pits.

(Capacities of 30,000 to 80,000 Lbs.)

Specialty

NORDOCK® offers a complete line of fully customizable vertical and horizontal storing rail dock levelers, extra wide levelers, and levelers for those who cannot (or prefer not to) build a conventional recessed pit in their building.

-

XTRA-WIDE™

(MODEL XW)The Model XW allows full access above and below service range for the widest loads that simply cannot be managed with conventional levelers.

(Capacities of 50,000 to 100,000 Lbs.)

-

BOXCAR™

(MODEL NR)The Model NR is designed for safe and efficient loading and unloading of rail cars. Custom built to suit rail position, door width and desired capacity.

(Capacities of 30,000 to 80,000 Lbs.)

-

BOXCAR™

(MODEL SRD)The Model SRD is equipped with all the standard performance features needed for safe and efficient loading and unloading of rail cars.

(Capacities of 40,000 to 80,000 Lbs.)

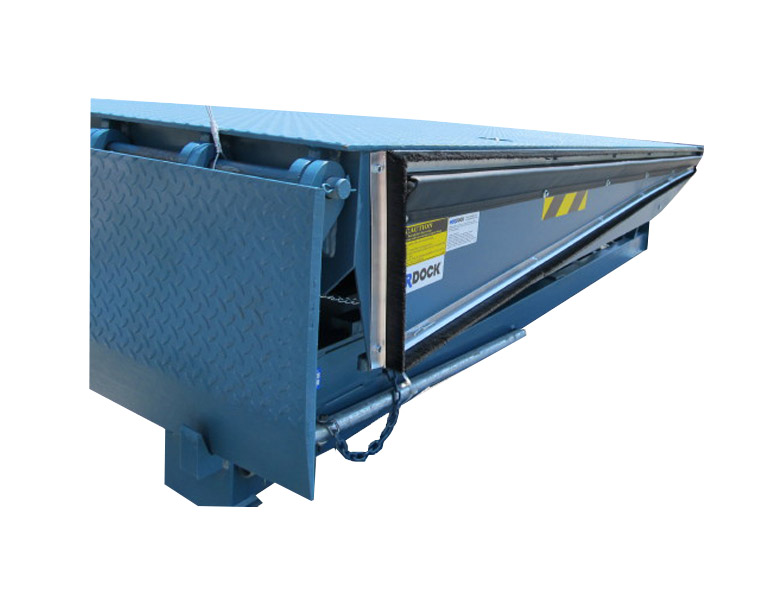

Hydraulic

Activated by a push button, the hydraulic system offers convenience and capacity for heavy use.

-

CONSTRUCTOR™

(MODEL CH)The Model CH is the economical choice designed for new construction, offering the least amount of parts in the industry.

(Capacities of 30,000 to 45,000 Lbs.)

-

DUAL-DUTY™

(MODEL ND)The Model ND patented hydraulic system utilizes a single hydraulic cylinder to lift the deck and lip.

(Capacities of 20,000 to 50,000 Lbs.)

-

HEAVY-DUTY™

(MODEL NH)The Model NH is fully featured with hydraulic powered deck and lip functions controlled by a single push button.

(Capacities of 25,000 to 55,000 Lbs.)

-

SUPER-DUTY™

(MODEL SD)The superior Model SD is designed to handle the heaviest applications and offers the highest capacity in the industry.

(Capacities of 60,000 to 160,000 Lbs.)

-

FALL-SAFE™

(MODEL SBL)The Model SBL’s exclusive patented design features a sliding lip to prevent accidental fall-off when stored.

(Capacities of 30,000 to 80,000 Lbs.)

-

BARRIER™

(MODEL NB)The Model NB is equipped with a STAY-PUT™ barrier lip, this leveler prevents accidental fall-off in its stored position.

(Capacities of 30,000 to 160,000 Lbs.)

-

FLEX-LIP®

(MODEL SHF)The Model SHF features the smoothest transition from trailer to dock, reducing driver fatigue and damage to goods.

(Capacities of 30,000 to 60,000 Lbs.)

-

Vertical Storing

(MODEL NV)The Model NV provides maximum energy efficiency, cleanliness, and is ideal for climate-controlled facilities.

(Capacities of 25,000 to 60,000 Lbs.)

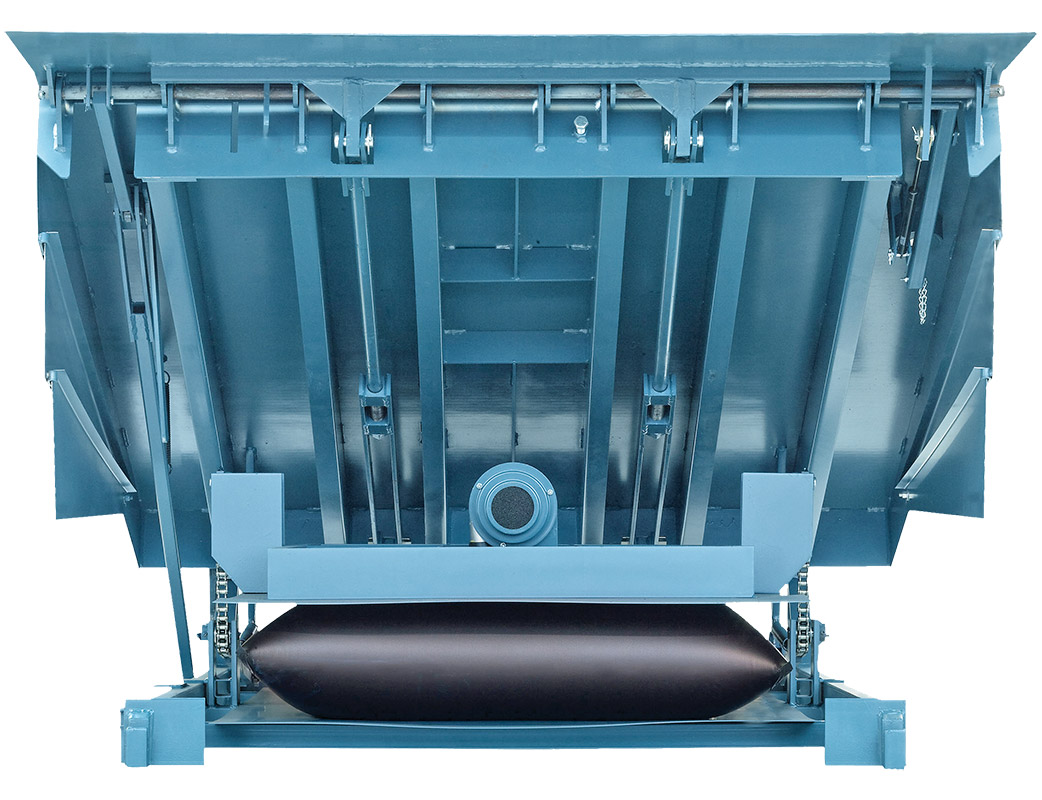

Air-Powered

Powered by Next Generation Air technology, these levelers are easy to use and require minimal maintenance.

-

AIRDOCK® CONSTRUCTOR™

(MODEL CA)The Model CA is the economical choice designed for new construction.

(Capacities of 30,000 to 45,000 Lbs.)

-

AIRDOCK® INDUSTRIAL™

(MODEL AD)The Model AD features the AUTO-DESCENT LIP™ fully yieldable extension system, which uses the natural weight of the deck to activate the lip.

(Capacities of 25,000 to 50,000 Lbs.)

-

AIRDOCK® SUPER-DUTY™

(MODEL SA)The Model SA is the toughest air powered leveler ever built with a 60,000 lb. capacity.

(Capacity of 60,000 Lbs.)

-

FLEX-LIP® AIRDOCK®

(MODEL ADF)The Model ADF eliminates lip crown, providing the smoothest transition of any leveler on the market.

(Capacities of 30,000 to 50,000 Lbs.)

Mechanical

An economical and tough solution with our easy walk-out lip extension.

-

CONSTRUCTOR™

(MODEL CM)The Model CM is the economical choice designed for the construction industry. Equipped with a tube style lip hinge.

(Capacities of 30,000 to 45,000 Lbs.)

-

INDUSTRIAL™

(MODEL NM)The Model NM is the economical choice providing the ultimate in strength and reliability. Equipped with a lip lug hinge for low maintenance.

(Capacities of 25,000 to 60,000 Lbs.)

Edge

Efficient alternatives for loading docks without a conventional pit.

-

LEVER™

(MODEL EM)The Model EM features a self-cleaning lip lug style front hinge assembly designed for longer life.

(Capacities of 20,000 to 50,000 Lbs.)

-

PUSH-BUTTON™

(MODEL EH)The Model EH is designed with ease of use in mind and includes a lift cylinder and mechanical lip extension.

(Capacities of 20,000 to 30,000 Lbs.)

-

PUSH-BUTTON™

(MODEL EFH)The Model EFH is a convenient fully hydraulic leveler with lift and lip extension cylinders and higher capacity.

(Capacities of 20,000 to 80,000 Lbs.)