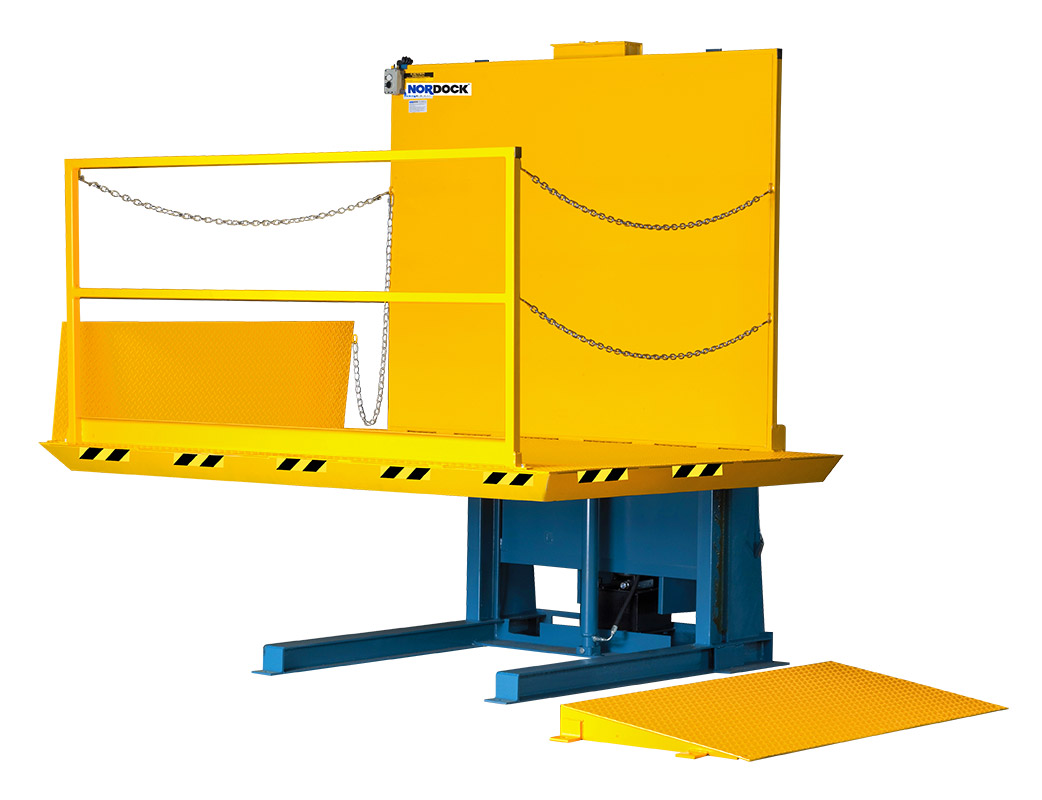

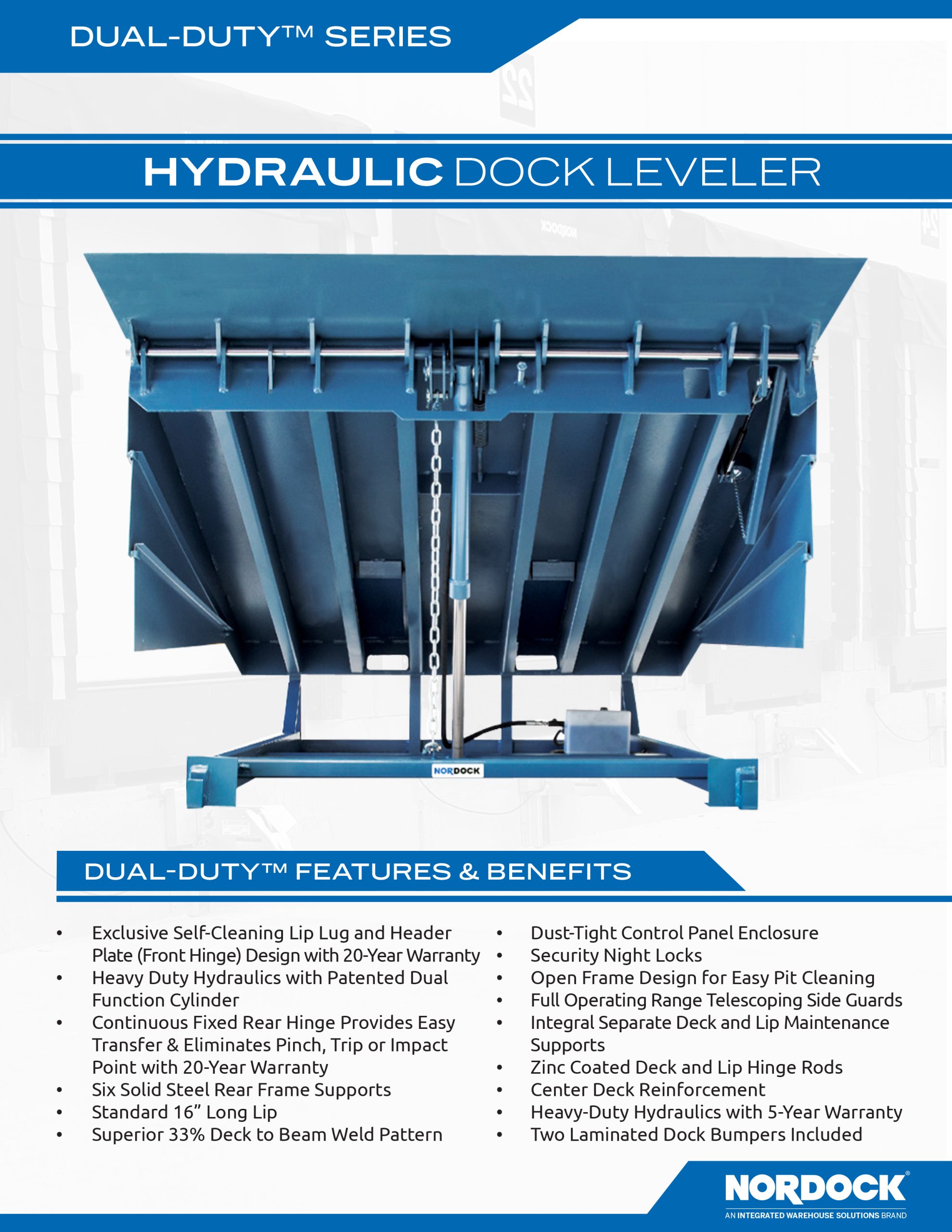

OPERATION

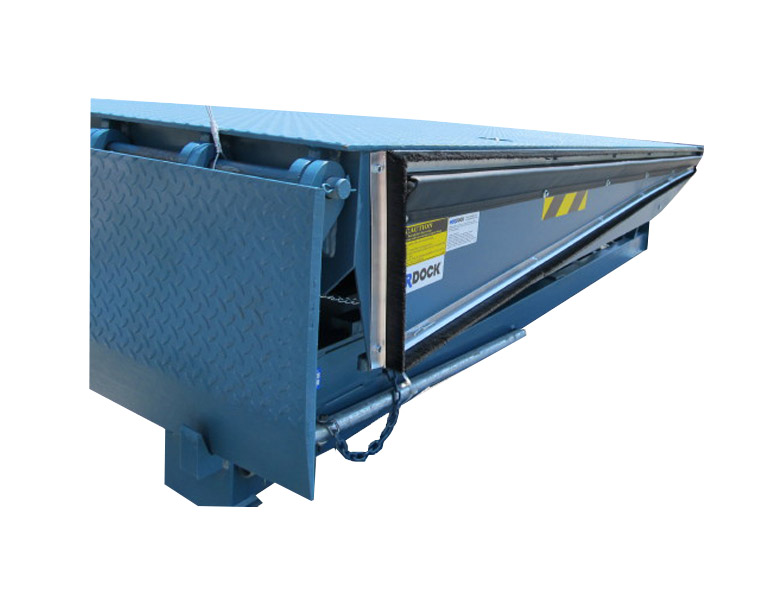

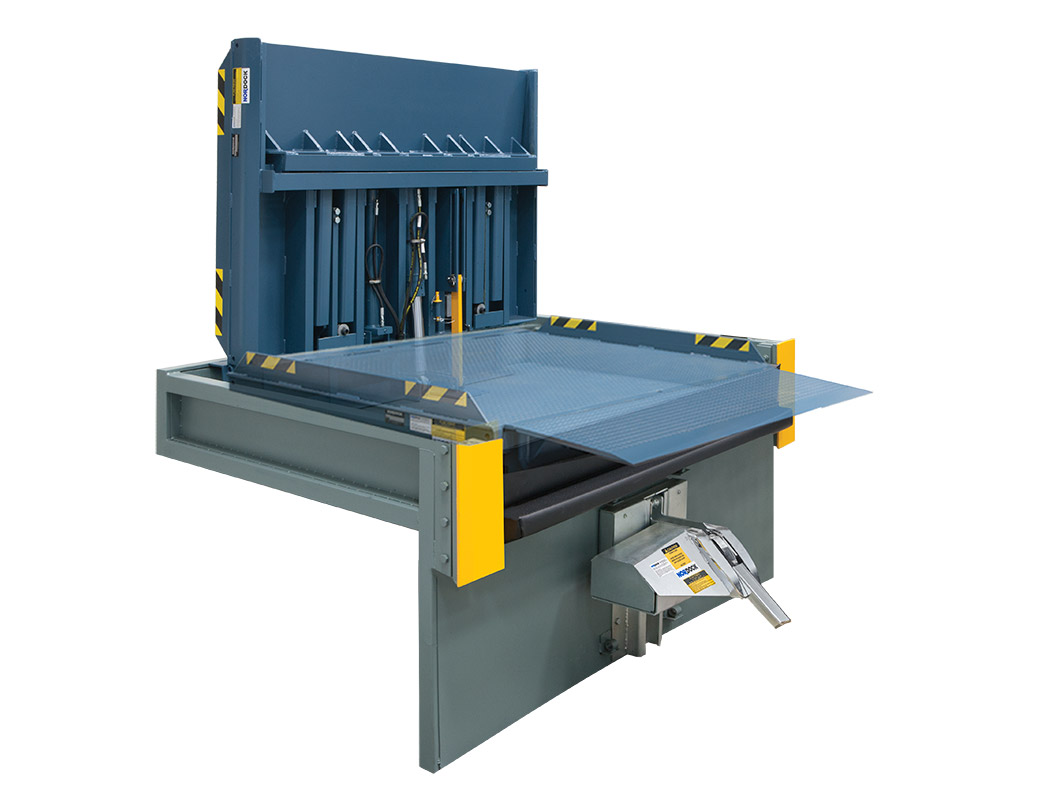

The operator presses the control button until the deck is raised, and the lip is fully extended. Releasing the button allows the lip to lower onto the truck bed.

The operator stores the leveler by pressing the control button until the lip fully retracts. The standard 16″ long lip projects 11″ beyond a 4″ bumper to engage a truck bed 12″ above or below floor level.

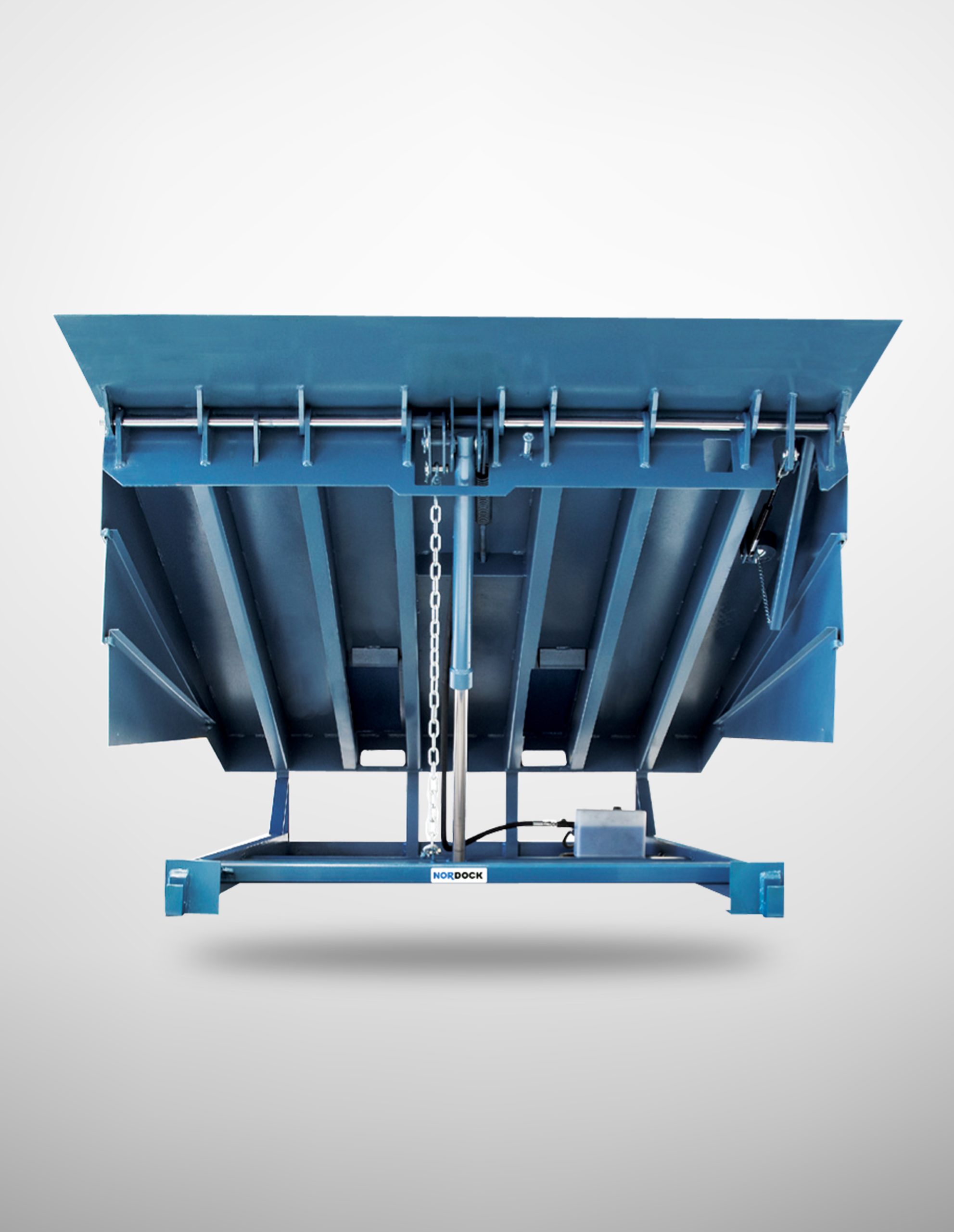

CONSTRUCTION

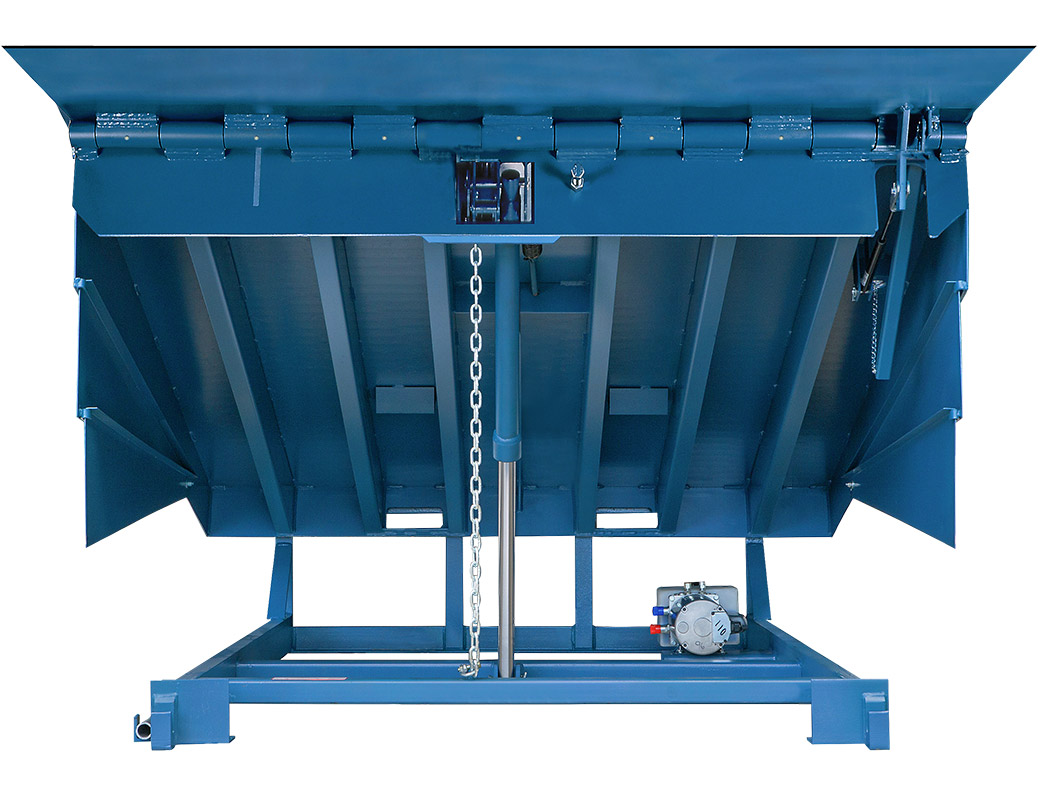

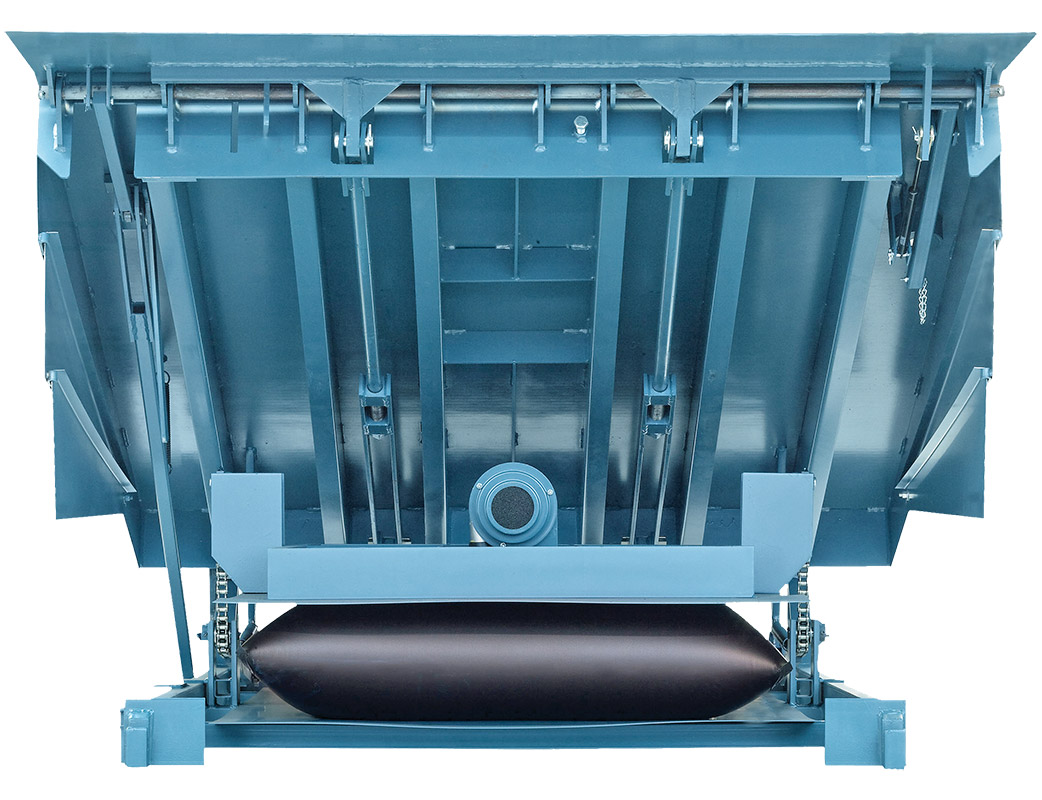

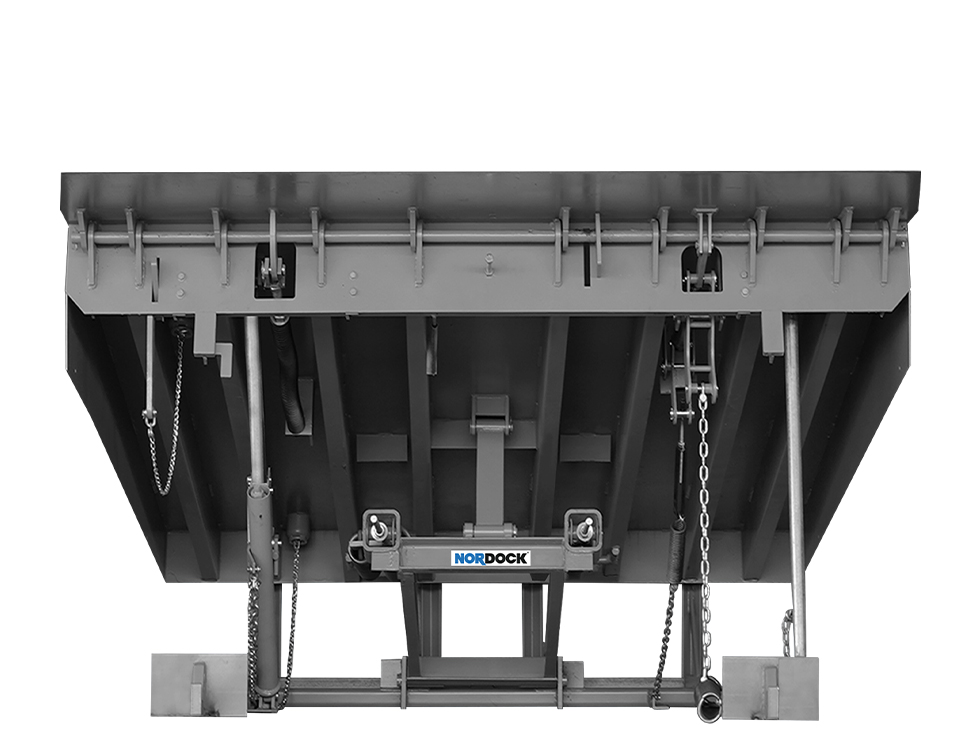

The platform is a unitized welded structure with continuous welds at the beam, header plate and lugs for maximum strength. The deck plate, lip plate, beam sections and lugs are constructed of minimum 55,000 PSI yield material.

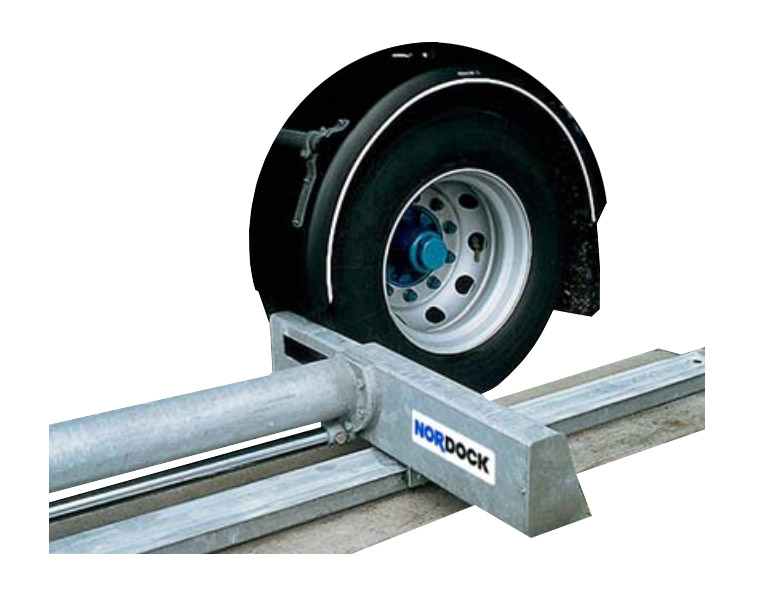

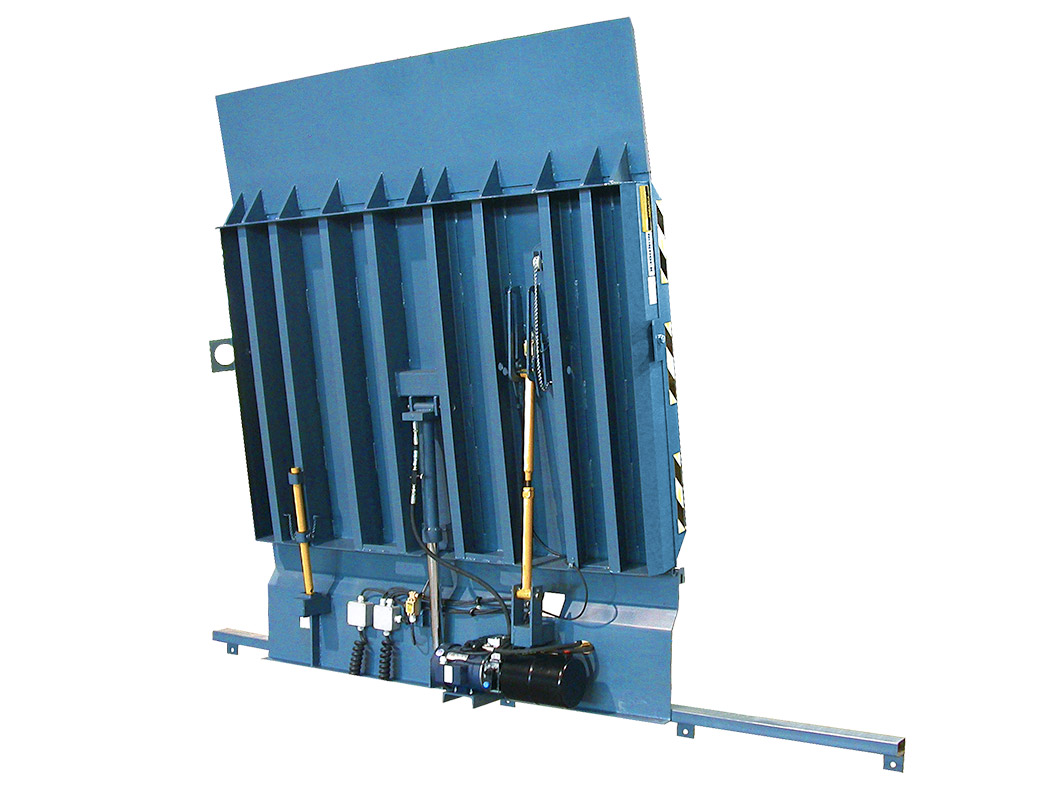

A standard center deck reinforcement beam and welded side guards provide additional deck plate support. The continuous rear hinge provides 4” of side-to-side tilt with no pinch point. The frame has six solid steel rear supports, an open design for easy pit cleaning and lip supports that prevent illegal entry when the door is closed.

The front and rear hinge rods are SAE 1045 material, zinc plated and factory coated with anti-seize lubricant.

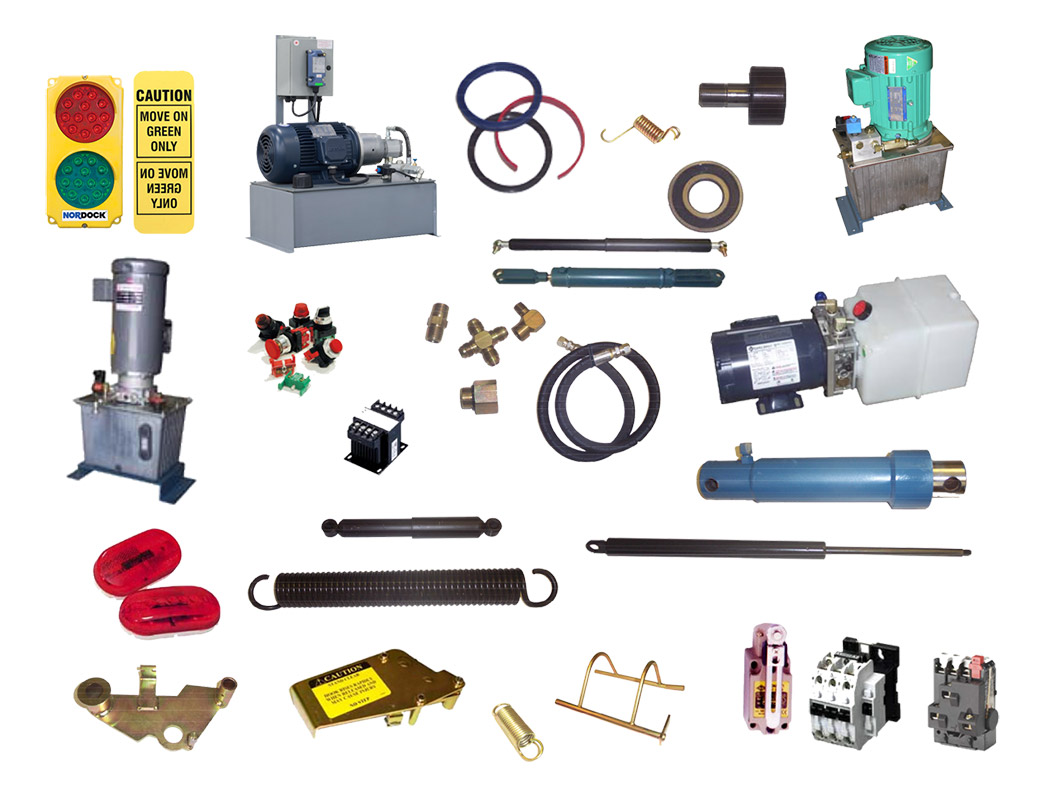

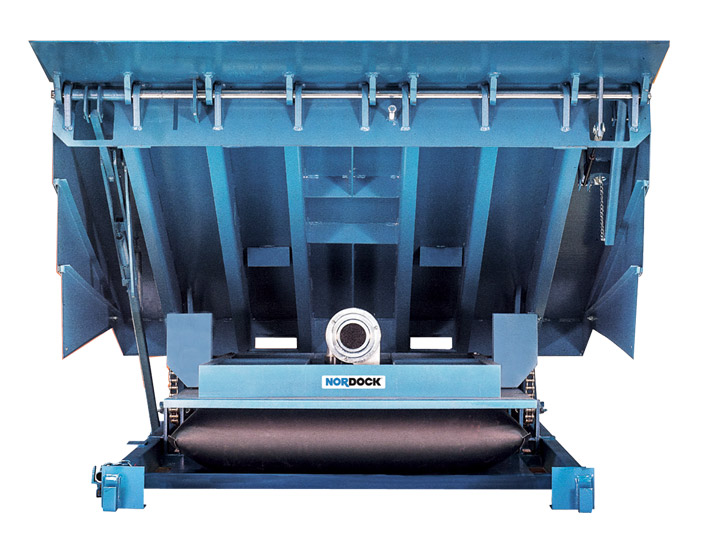

ELECTRICAL/HYDRAULICS

The power unit is a frame mounted integral assembly fully tested and oil filled. The motor is a totally enclosed non-ventilated type available in all voltages. The control box is a dust-tight enclosure with motor starter, thermal overload and single push button.

The hydraulic cylinder is a heavy-duty design with a polished chrome rod, guide bearing and high-pressure seals. The hydraulic hose is SAE 100R2 with permanent fittings attached.

WARRANTY

NORDOCK® guarantees that the DUAL-DUTY™ Series of hydraulic dock levelers will perform as described and to the full satisfaction of the purchaser for one-year from date of receipt.

In addition, structural components are guaranteed for ten-years under specified guidelines. All NORDOCK® dock levelers are designed to exceed the safety and performance requirements of ANSI MH30.1 – 2007 and when properly applied comes with a 10-year structural warranty and 5-Year Hydraulic.