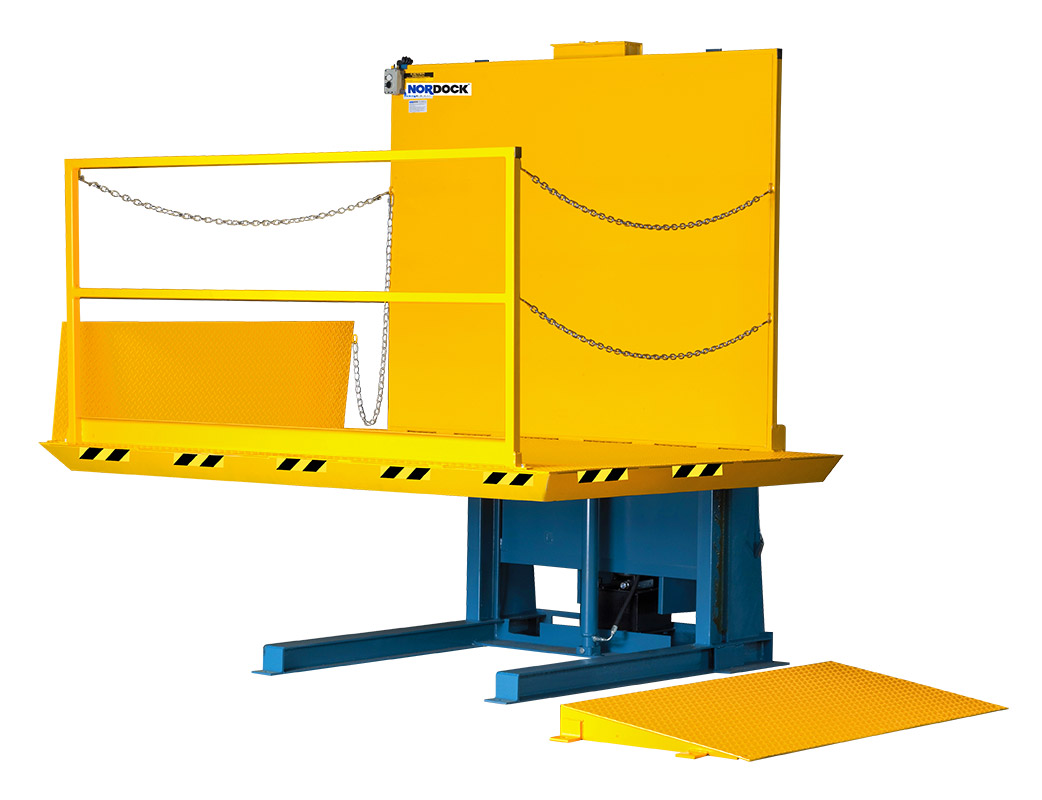

FLIP YOUR EXPECTATIONS

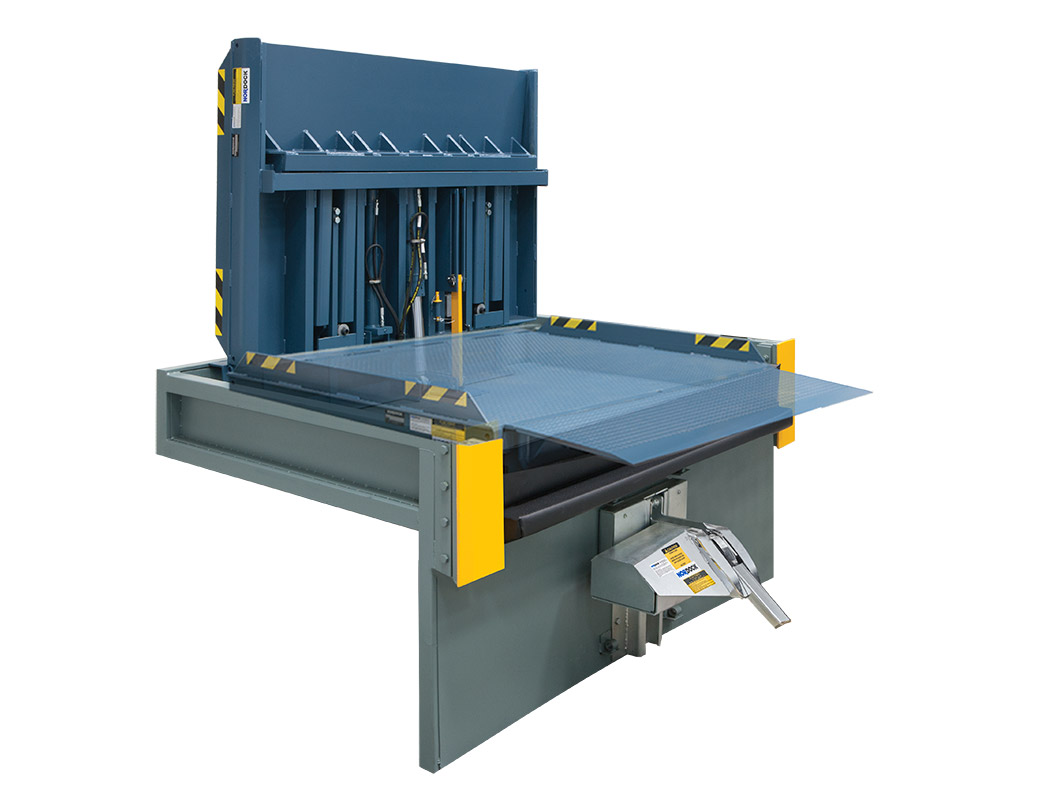

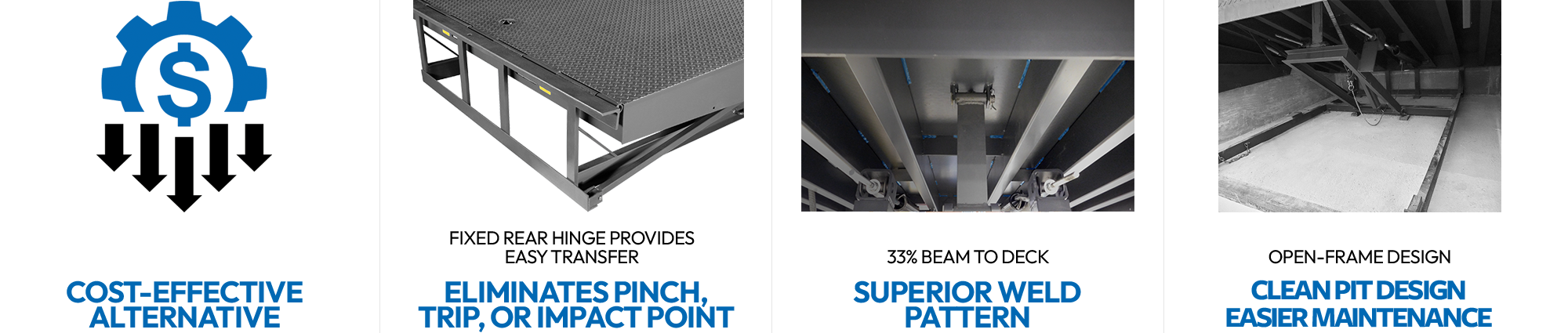

The ELEMENT Series redefines reliability, value, and performance. It is designed to withstand the demands of high-traffic loading docks and fits a wide range of applications, from newly constructed buildings to existing sites that need a refresh.

Built for longevity, the Element has been tested to over 50,000 cycles. Additionally, we performed dynamic load testing ensuring it meets the highest durability standards.

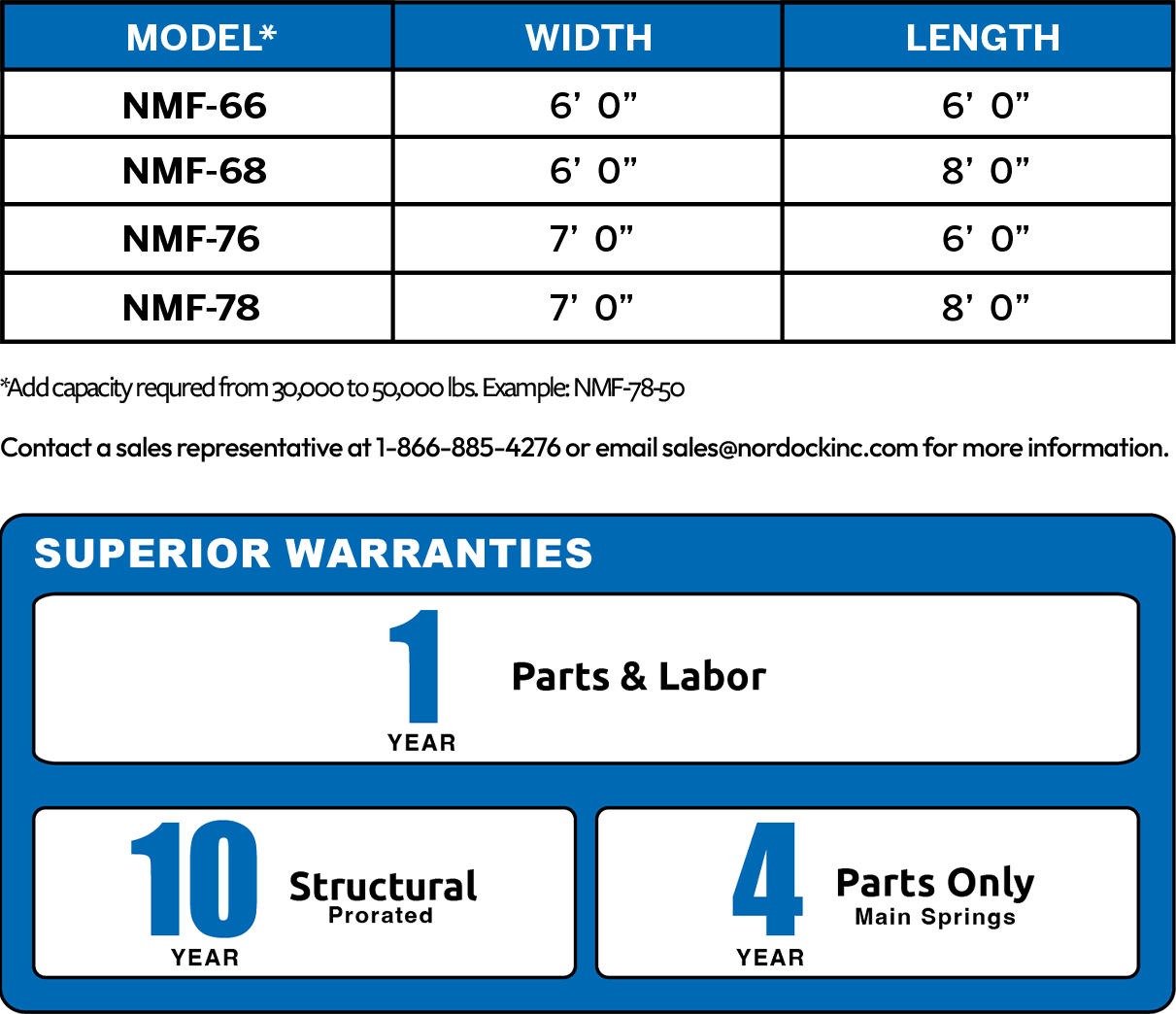

Available in capacity ratings from 30,000 to 50,000 lbs., in 5,000 lb. increments, and available in standard sizes of 6′ and 7′ wide by 6′ and 8′ long.

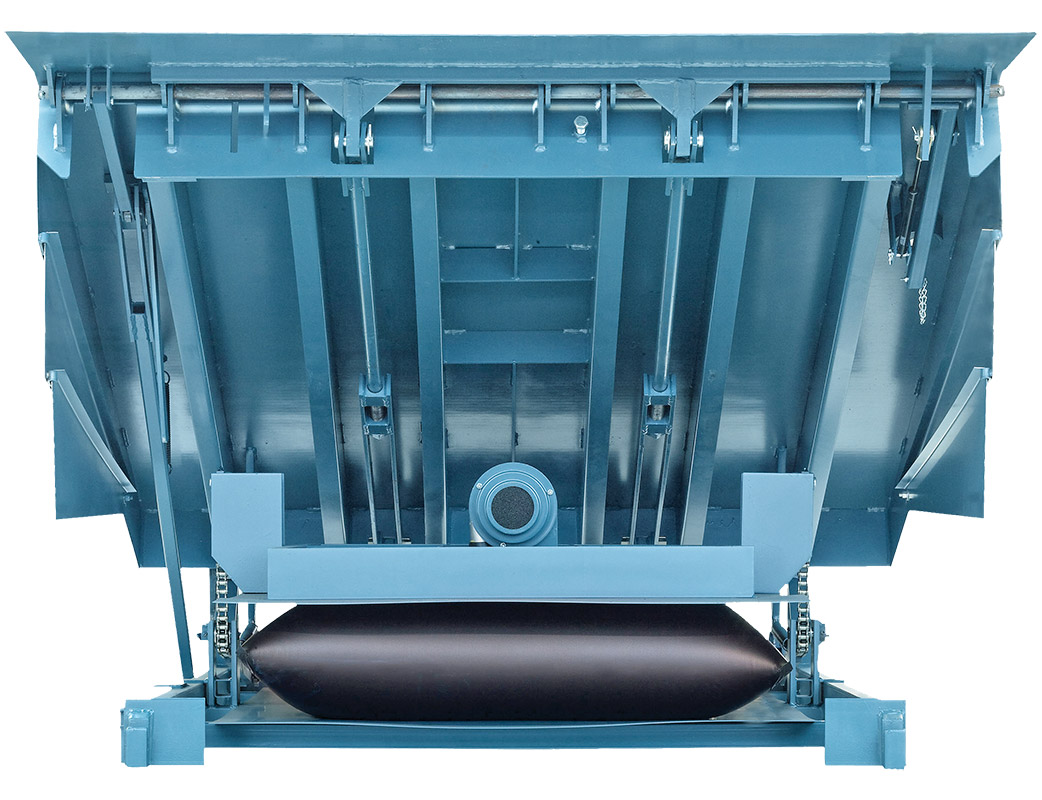

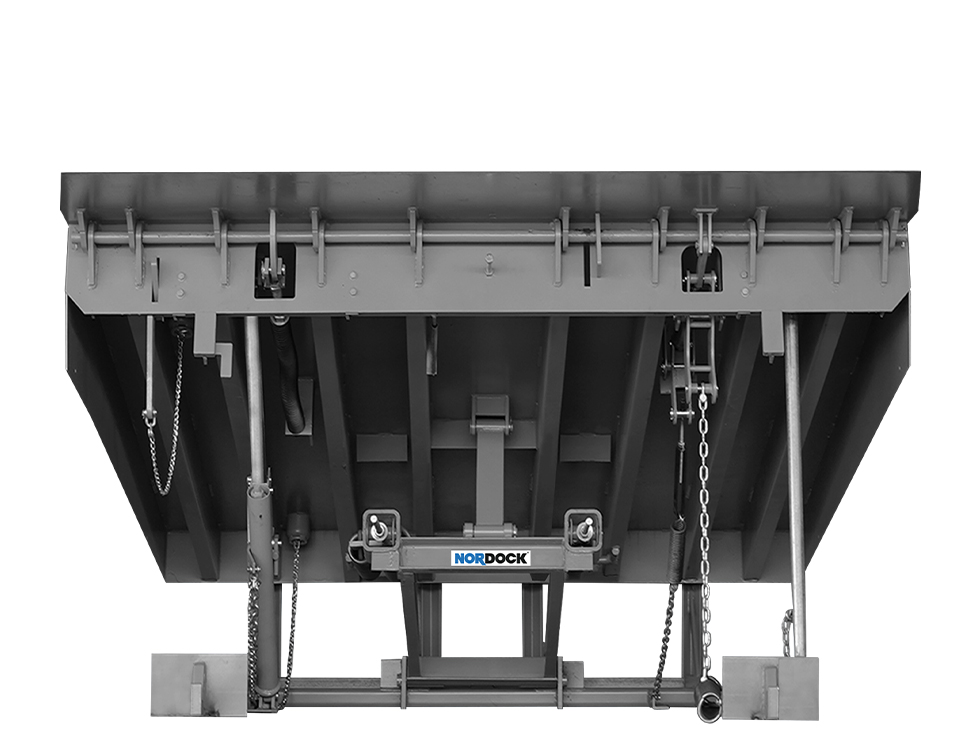

Engineered for performance, standard features include a self-cleaning lug-style hinge design to prevent debris buildup & a clean pit design ensuring easy maintenance. The robust welds, self-leveling tabs, and zinc-coated hinge rods guarantee reliable performance.

Safety is enhanced with free-fall legs, a Safety Strut, and a center deck beam for extra support.

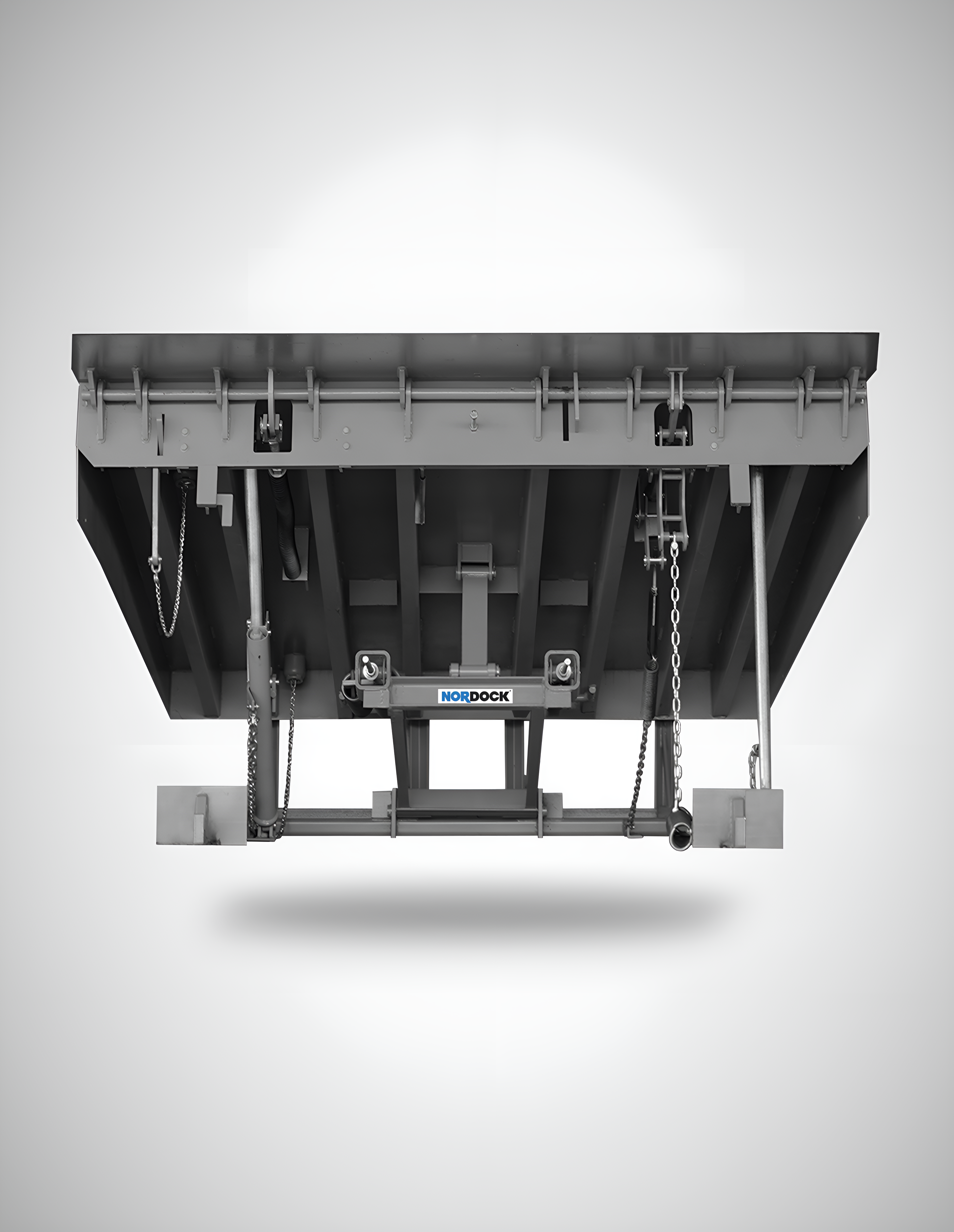

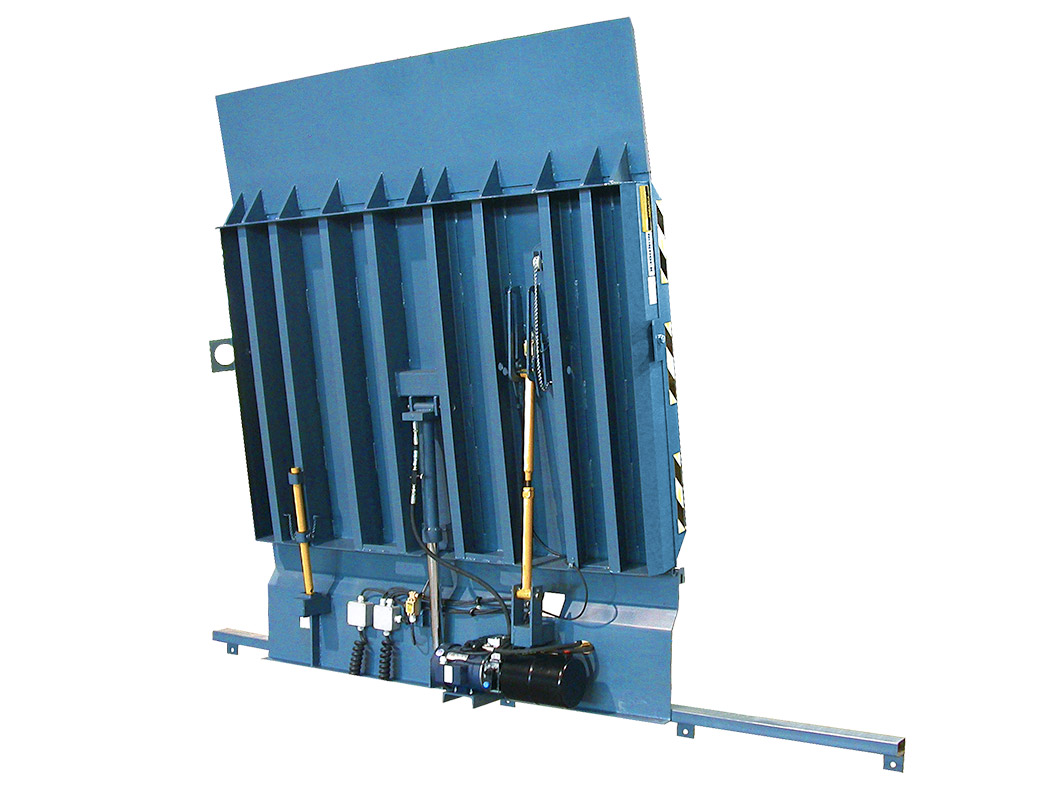

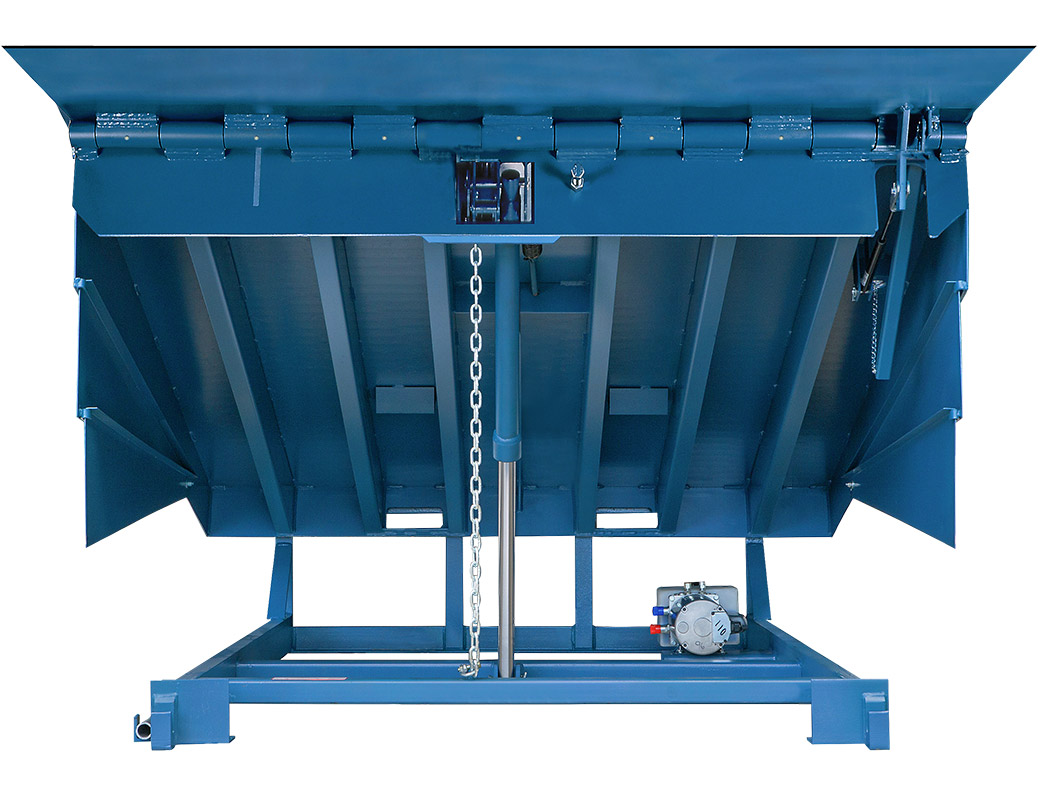

CONSTRUCTION

Strength and durability were top of mind when the Element was designed.

The deck features a unitized structure with a 33% dual side beam-to-deck weld pattern and continuous welds and the header plate and hinge tubs for enhanced strength.

The L-shape steel beams offer solid support, while the welded ramp design allows side-to-side tilt for uneven trailer beds. The subframe includes a rear structural angle and four solid steel rear supports. Lip supports also act as locks to prevent unauthorized access when the door is closed.

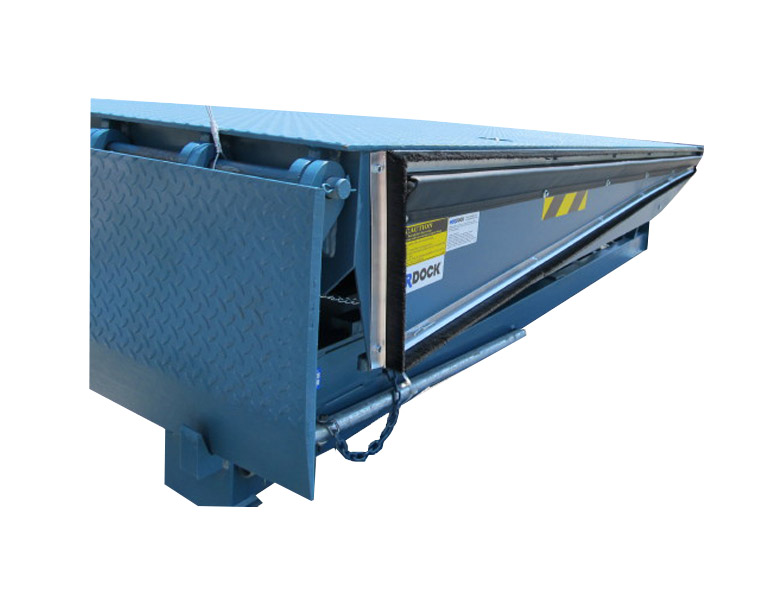

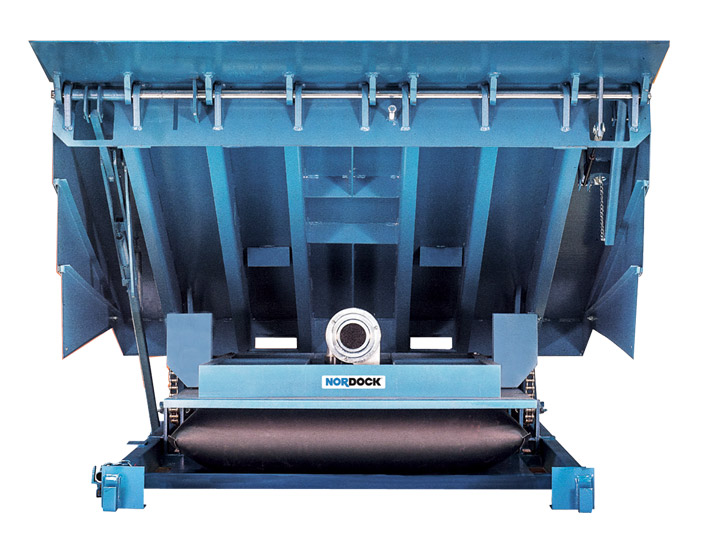

OPERATION

The operator pulls the chain to release the hold down, raising the deck to its highest position. As it raises, the standard 16″ lip extends, allowing it to engage a truck bed 12″ above or below floor level.

The ergonomic design allows the operator to effortlessly walk forward on the deck, lower it and extend the lip to engage the truck bed seamlessly.

Storing the leveler is equally simple. The operator pulls the chain and walks the deck down as the lip drops and settles into the hold-downs behind the dock bumpers.