OPERATION

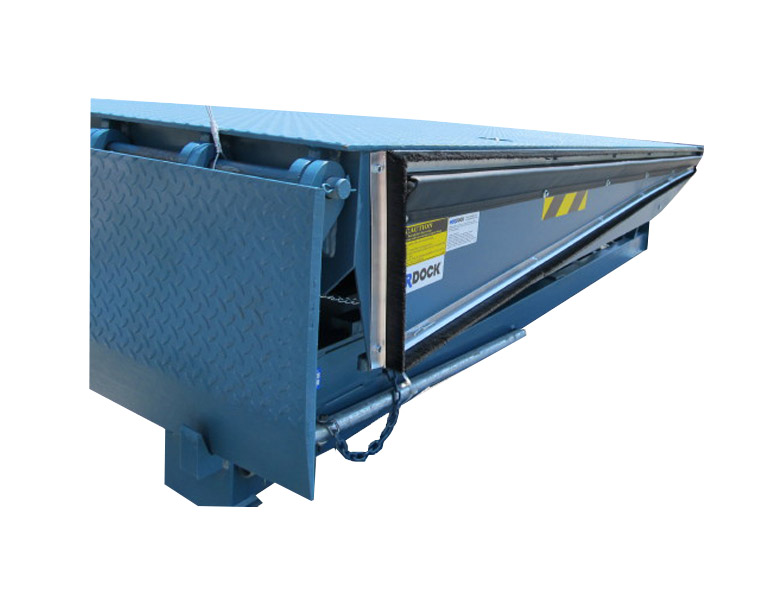

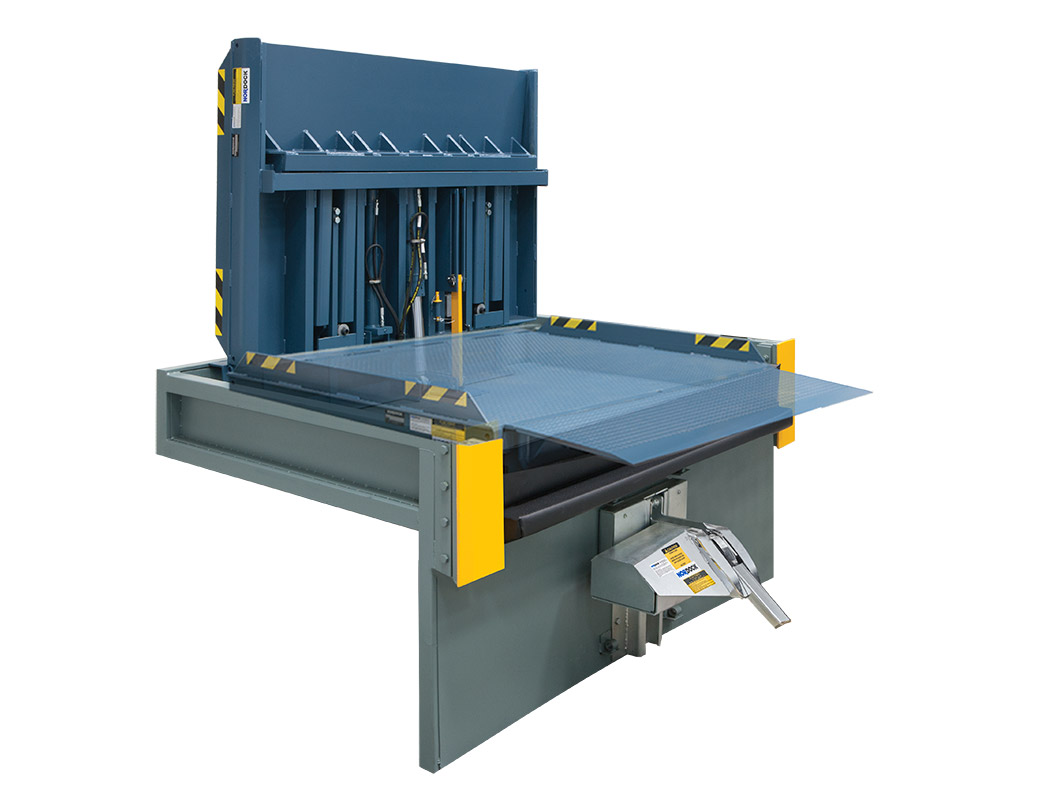

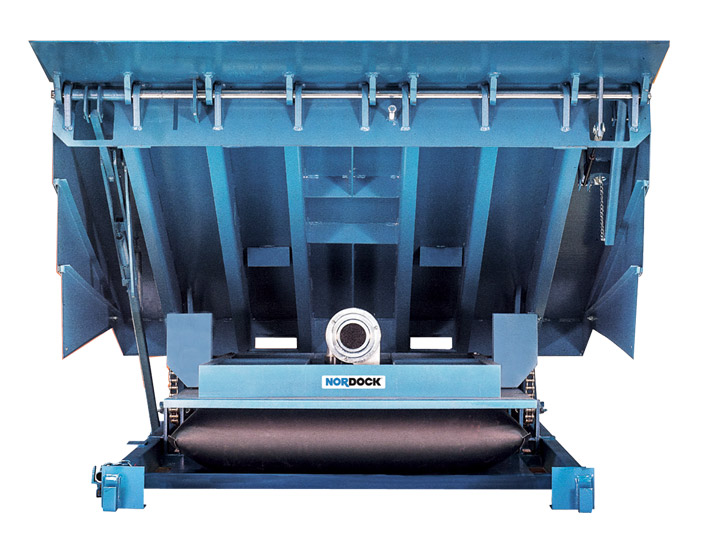

The operator presses the control button until the deck is fully raised. Releasing the button activates the AUTO-DESCENT LIP™ system that extends the lip as the deck lowers placing it smoothly onto the truck bed.

The leveler will float up and down and side to side with the truck during loading to maintain lip contact at all times. To store the dock leveler, the operator presses the control button that activates the lift system allowing the lip to automatically retract to a pendant position,

releasing the button deactivates the air power to store the leveler in a fully supported position level with the building floor.

The standard 16″ lip will extend out 11″ beyond a 4″ bumper and engage a truck 12″ above and below building floor level.

Note: Longer lip option reduces above dock service range.

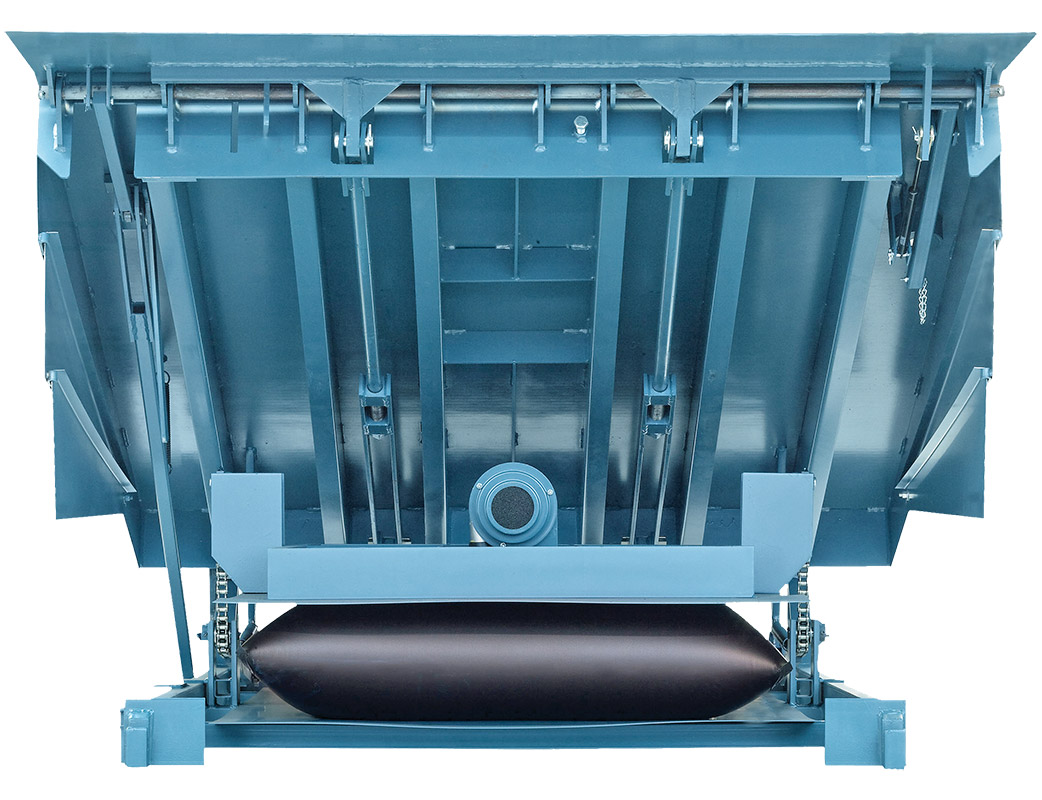

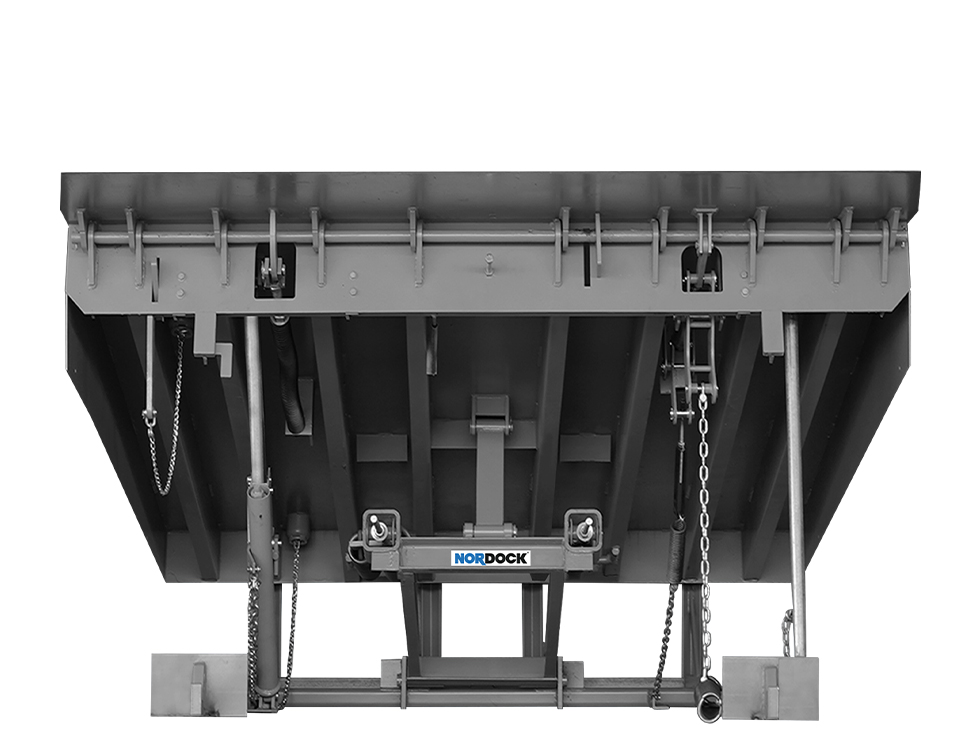

CONSTRUCTION

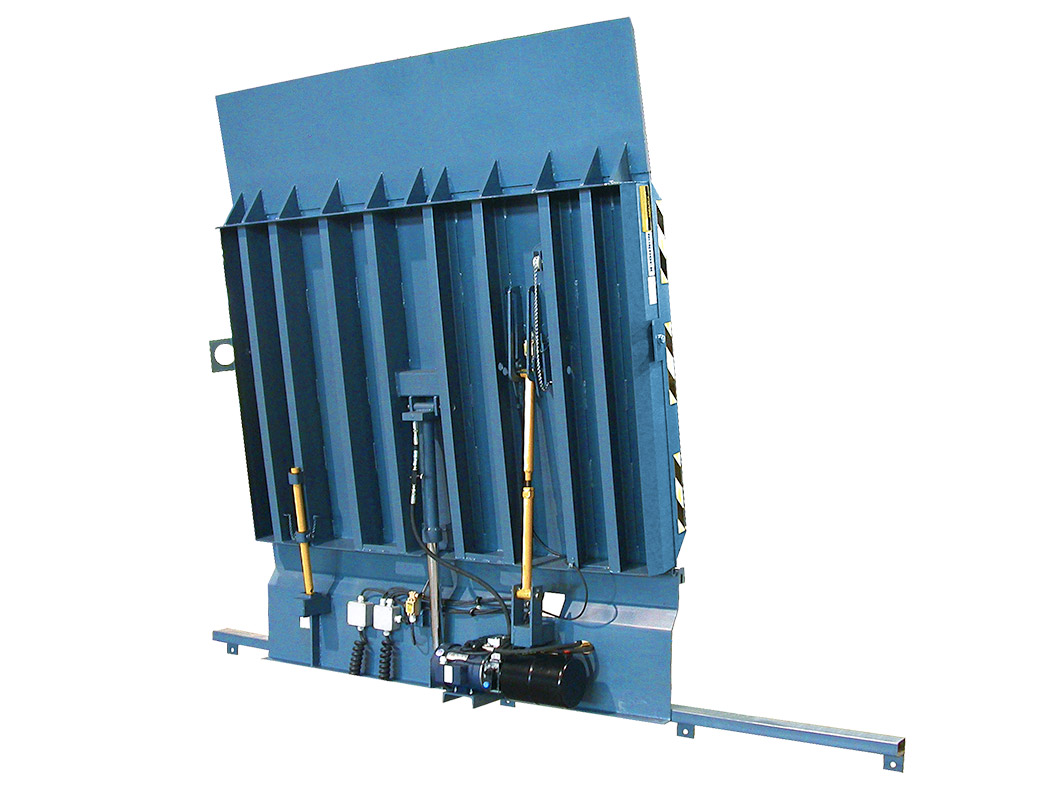

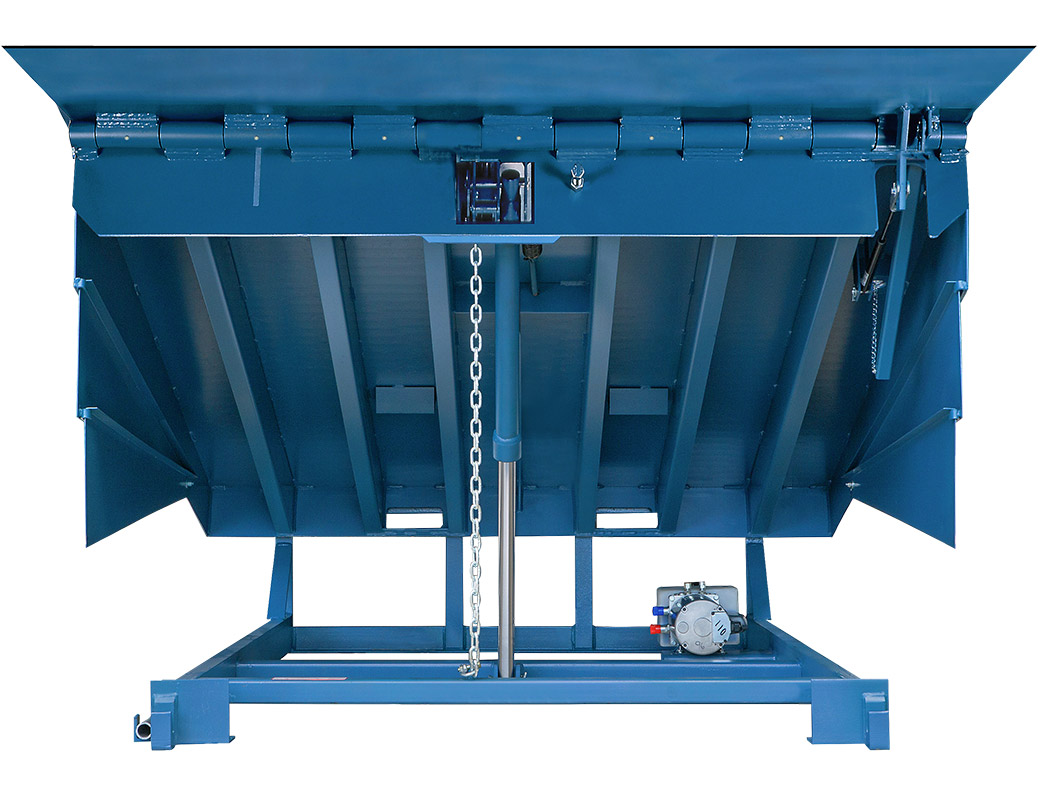

Unitized platform structure with dual side 33% beam to deck weld pattern and continuous welds at the header plate and hinge tubes for superior strength. The deck plate, lip plate and beams are constructed from high-tensile steel and safety tread top running surface.

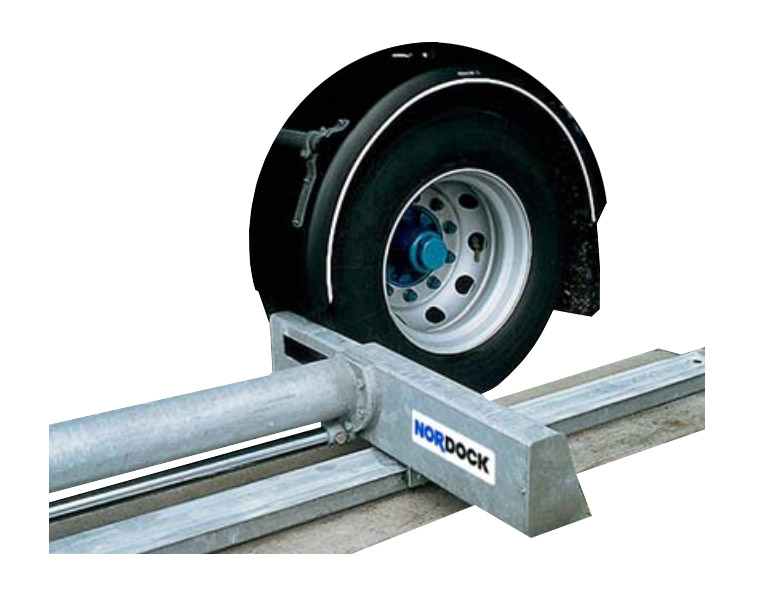

The frame has four upright and two forward supports with a fixed rear hinge connection to

eliminate pinch, trip or impact. A security lock system is provided to prevent illegal building entry when the overhead door is closed. Full width front and rear hinge rods are constructed

of SAE 1045 superior shaft and are factory coated with anti-seize lubricant. A single NEMA 4 push-button control operates the 120-Volt fan motor.

WARRANTY

NORDOCK® guarantees that the CA Model of air-powered dock levelers will perform as described and to the full satisfaction of the purchaser for one-year from date of receipt.

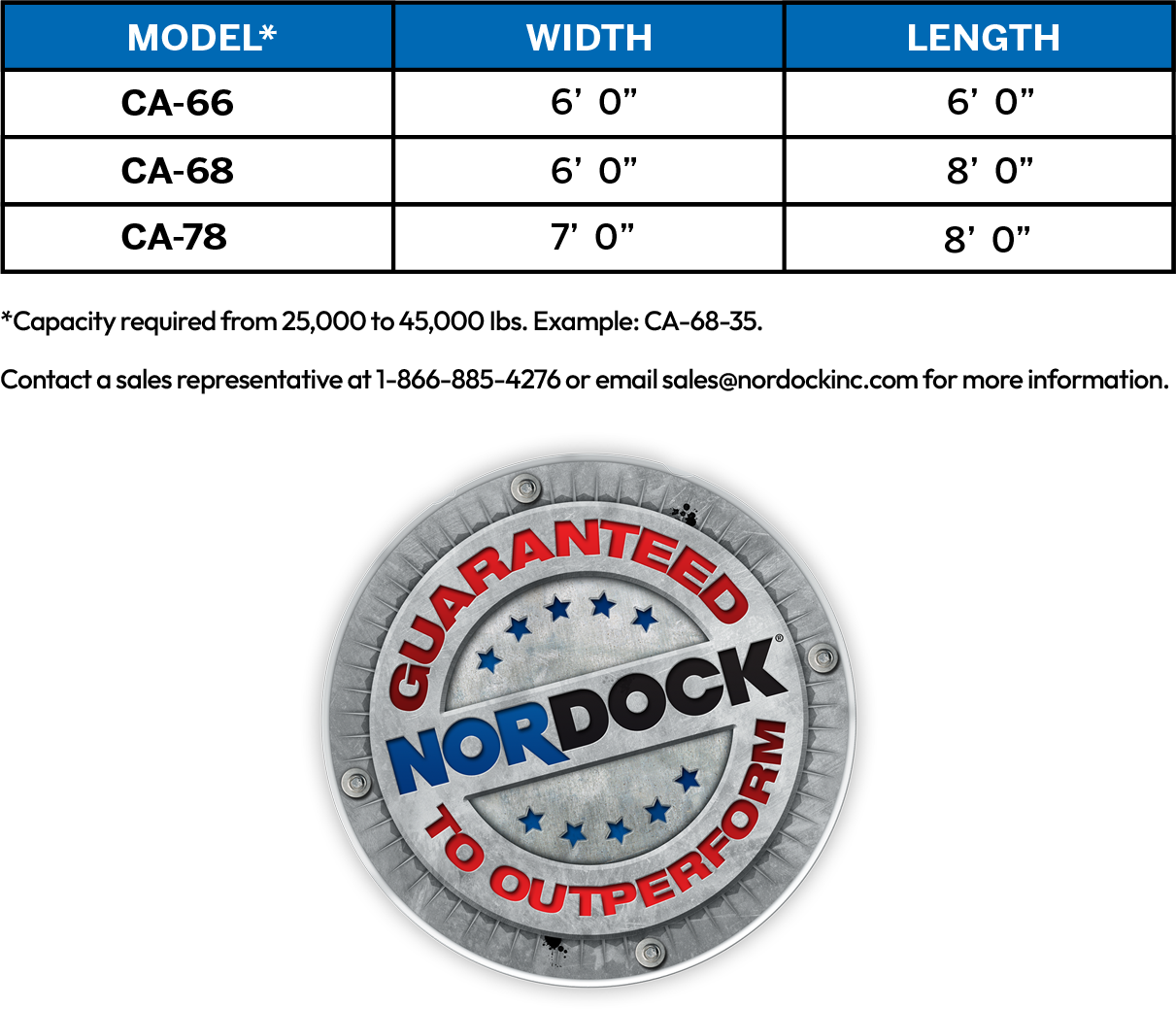

Consult your NORDOCK® representative for assistance in choosing the correct capacity and options for your application.

Dock Leveler Guide

NORDOCK® Dock Leveler Guide