Deck Sizes & Capacities

*16′ & 20′ lengths available from 10,000 lbs & up. Note: De-rate capacity by 40% for side loading. Consult factory for custom scissor lift applications up to 50,000 lb. capacity and 40 feet long.

Model # = Model+Deck Size+Capacity Example: DL-68-12 = 6’ x 8’ 12,000 lbs.

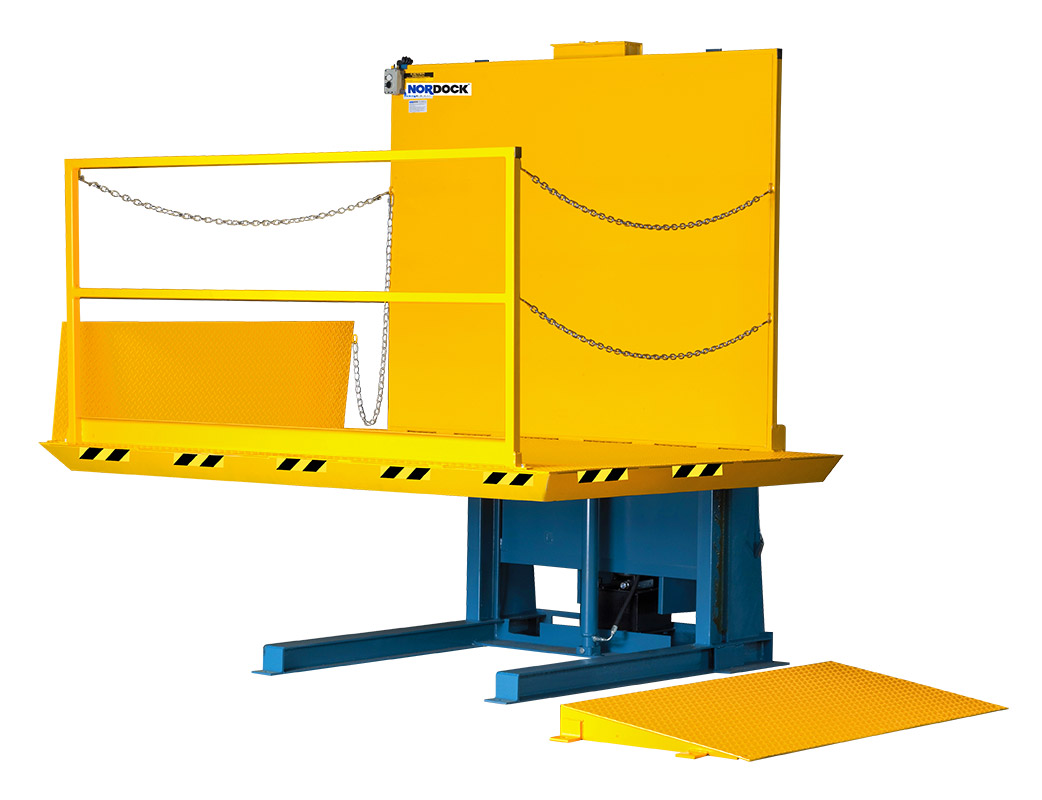

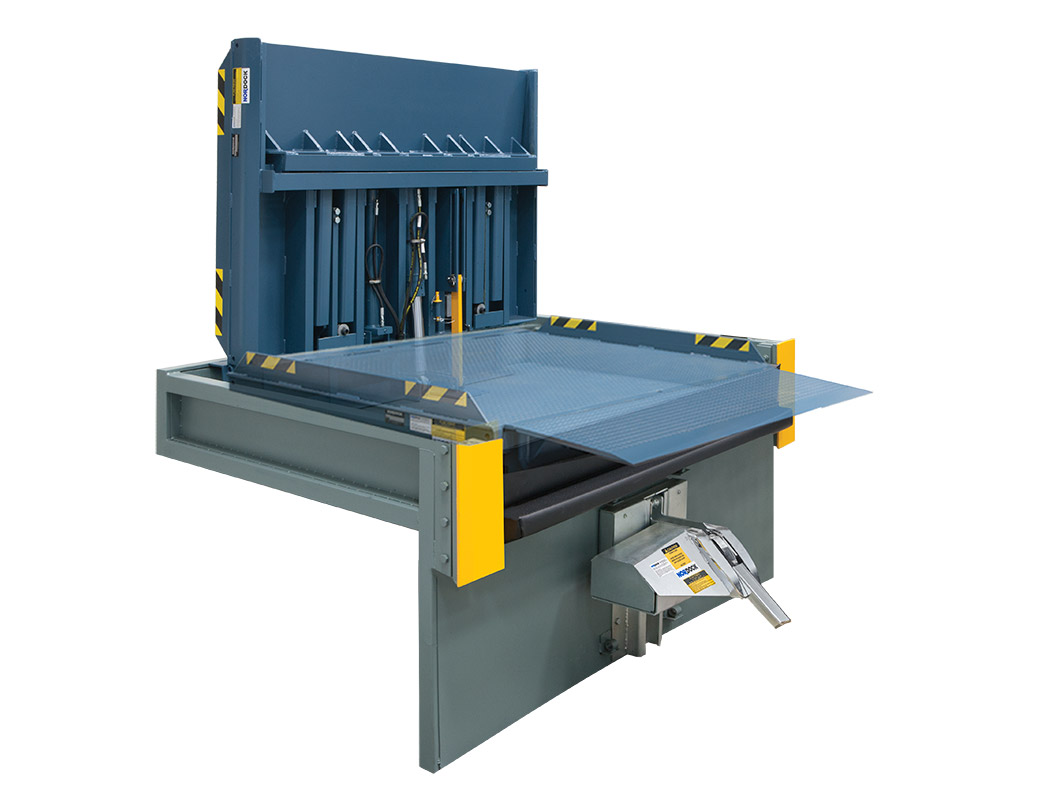

Operation

With the platform in its stored position the operator moves on to the platform and presses the raise button until the hinged bridge can be lowered on to the truck bed. Releasing the control button stops the platform movement. The operator can ‘inch’ the platform into position using the raise and lower buttons to ensure the bridge and platform are level with the truck bed.

To return the lift to its stored position the operator, raises the bridge to its upright position and presses the lower button until the platform is at rest, level with the ground or floor. The barrier chains are kept across the open ends of the handrails when the platform is raising or lowering. The standard 18″ long bridge should project at least 10″ beyond the bumpers or bollards. Vertical service range is from level to 60″ above floor.

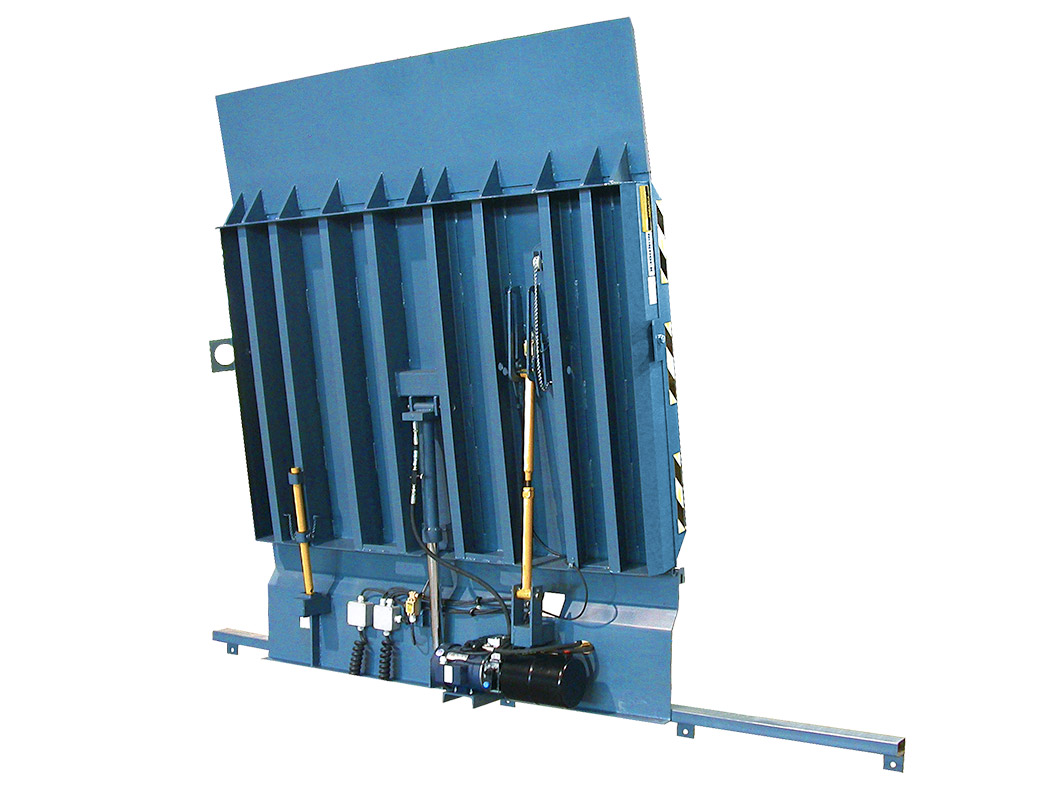

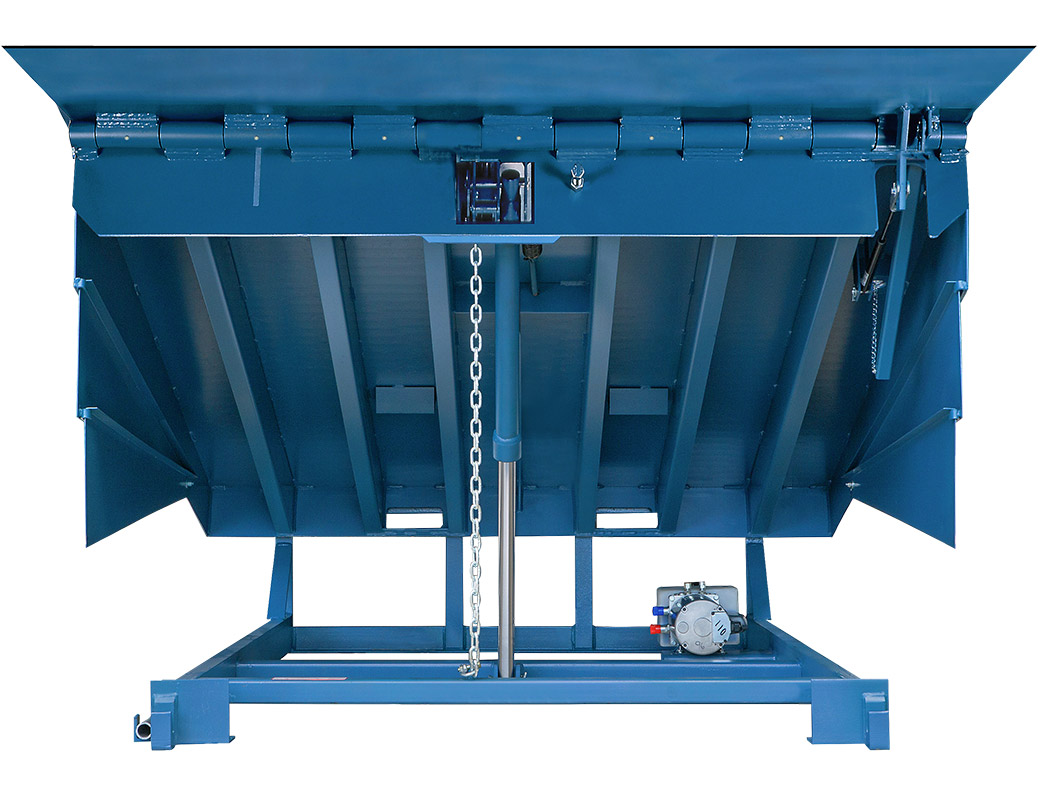

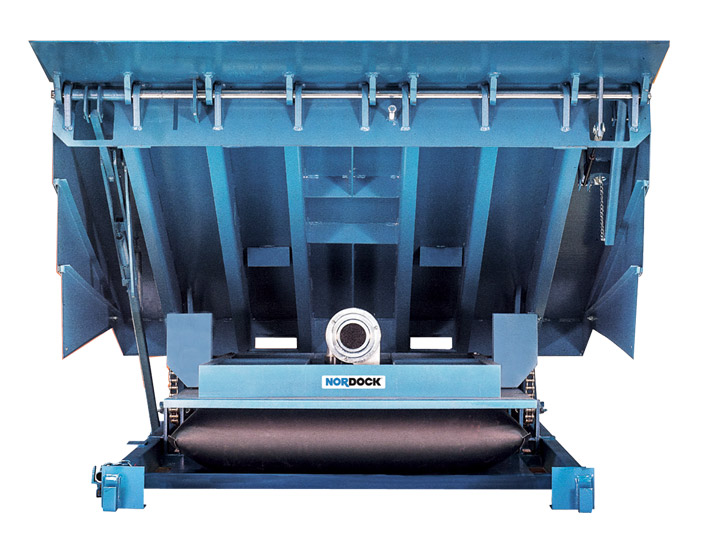

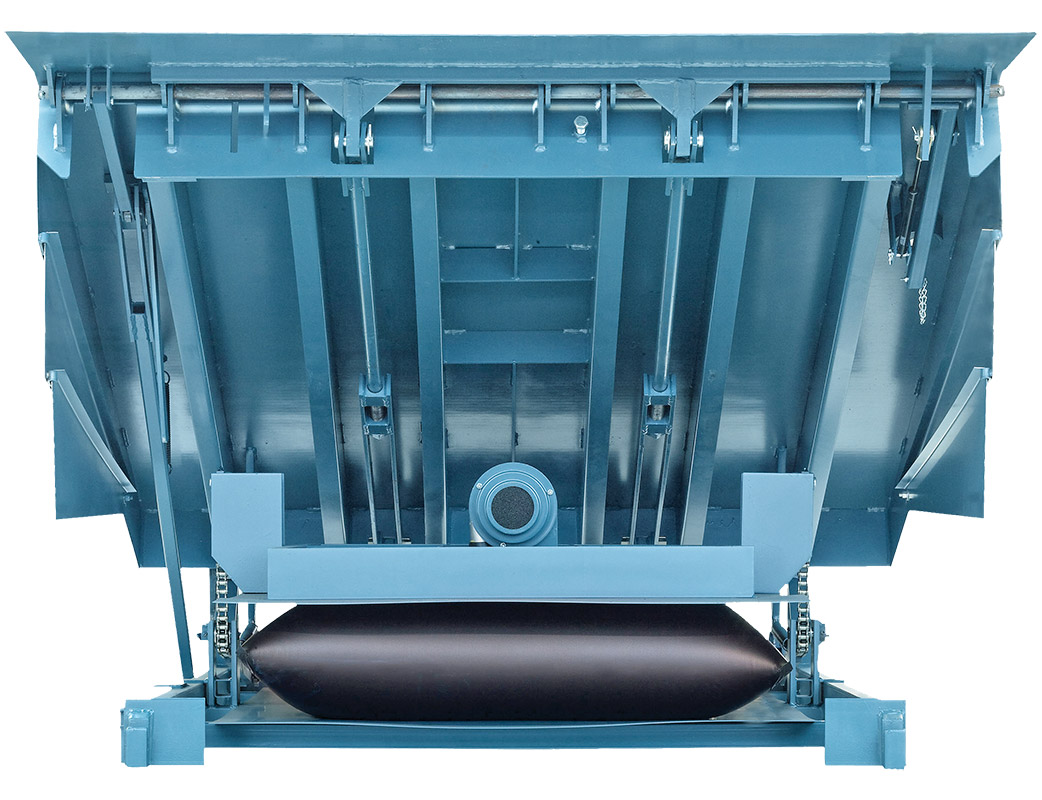

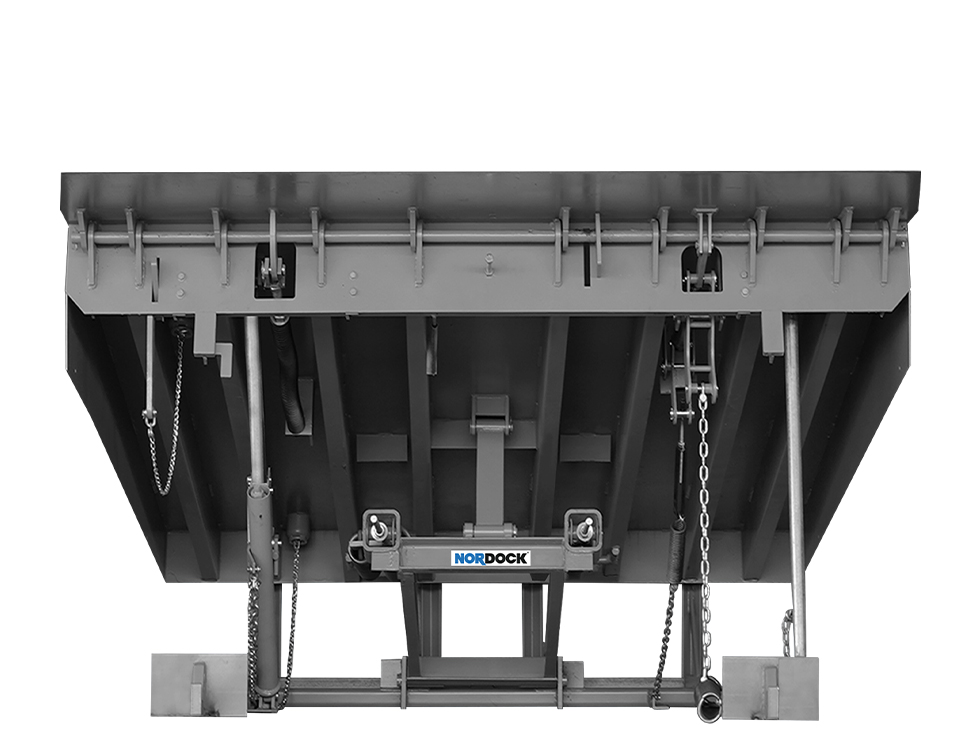

Construction

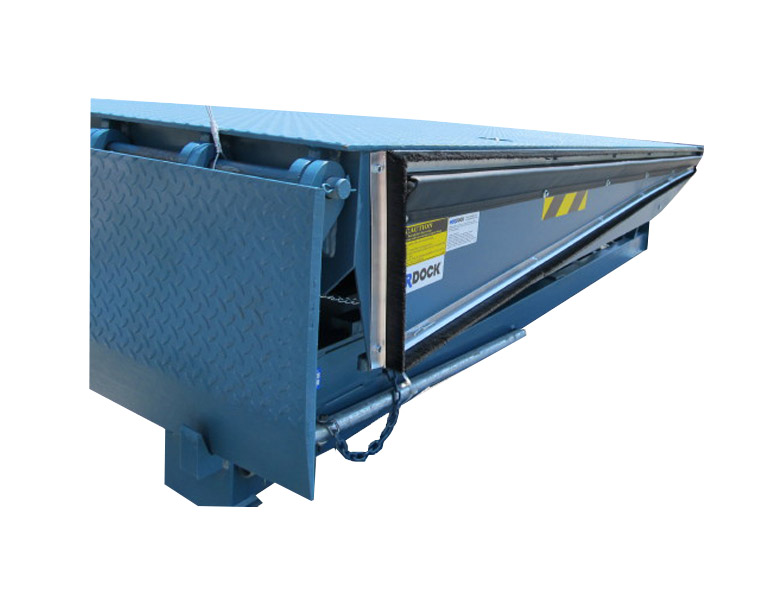

The platform is a unitized welded structure with a nonslip checker plate deck surface and beveled perimeter toe guards with black and yellow safety striping.

The scissor legs are constructed of solid high tensile steel plate and heavy wall structural cross tubes.

Self-aligning spherical bearings are utilized at the center scissor and cylinder base positions.

Lifetime lubricated bushings are used at all other pivot points.

Cam followers are provided for the rolling end of the scissor legs.

Two removable 42″ high handrails are provided, painted yellow with a 4″ high kick plate.

Restraint chains with snap releases are provided across the open ends of the handrails.

A steel checker plate hinged bridge with lifting chain is provided at one end of the platform.

A maintenance support is provided to support the empty lift in a raised position.

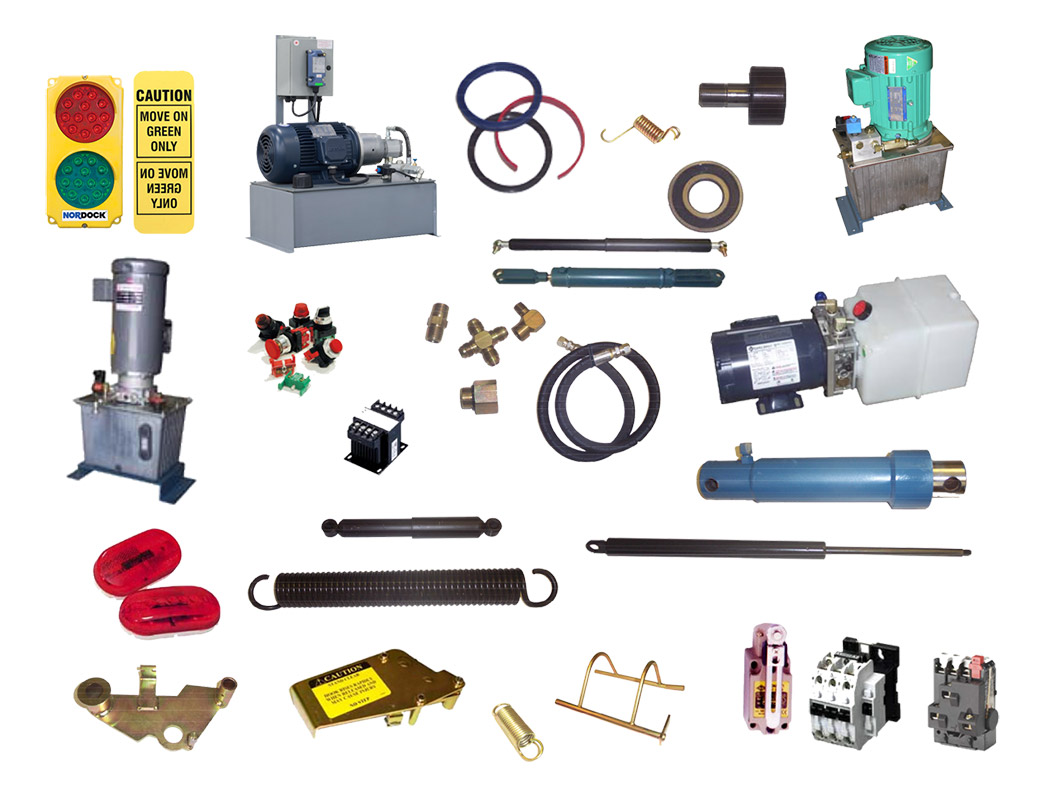

Electrical/Hydraulics

The power unit is a remote mounted assembly with a totally enclosed fan cooled motor, gear pump, valve manifold, relief valve, filters and oil filled reservoir. The control panel includes a NEMA 12 rated dust tight enclosure with motor starter, thermal overload, and a fused transformer to reduce the control voltage. The push button is a NEMA 4 rated weatherproof control attached to a retractable cord.

The hydraulic cylinders are a heavy-duty design with polished chrome rod, guide bearing, spherical bearing, and high-pressure low-friction seals. Velocity fuses are installed in the cylinders to arrest the descent of the lift if the oil pressure is interrupted. The hydraulic hoses are SAE 100R2 high pressure with permanent fittings attached.

Warranty

NORDOCK® guarantees that the DOCK-LIFT™ Series of hydraulic scissor lifts will perform as described for one-year from date of receipt.

In addition, NORDOCK® guarantees, under specified guidelines, the structural components for Ten-Years, and the hydraulic components for Five-Years. All NORDOCK® lifts are designed to exceed the requirements of ANSI MH29.1, Safety Requirements for Industrial Scissor Lifts.