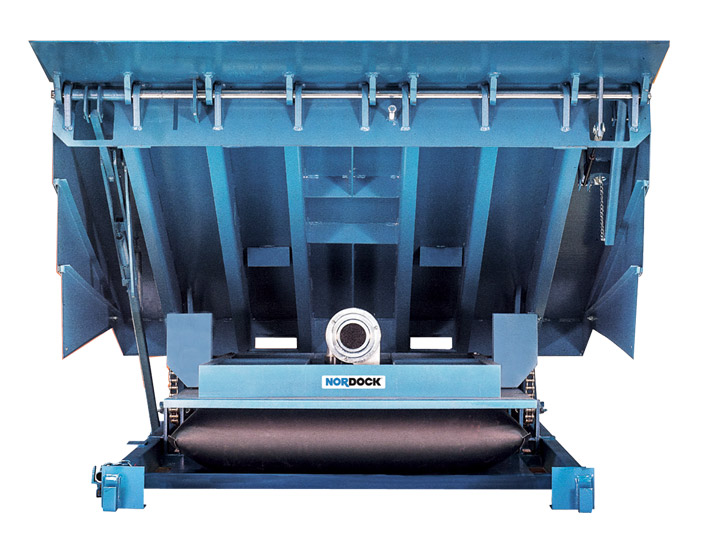

OPERATION

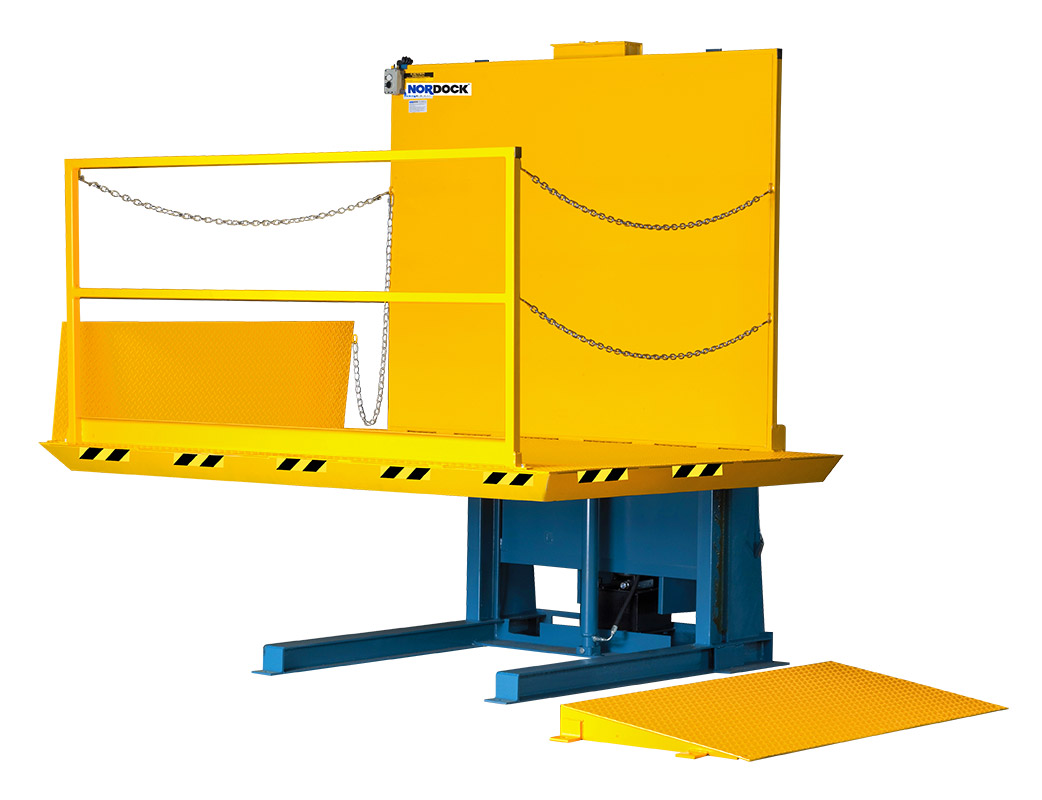

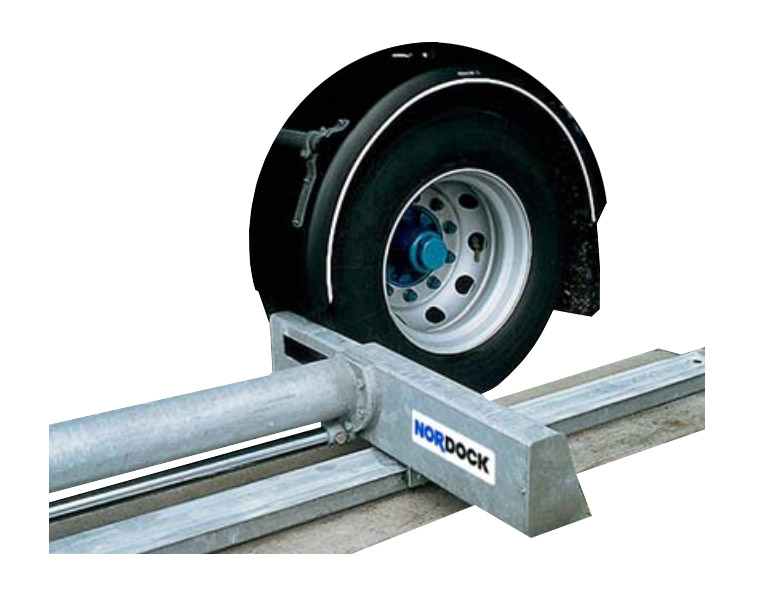

The operator presses the control button until the deck is fully raised. The EH model automatically extends the lip as it descends. The ramp shall be free to float with the up and down movement of the truck bed. The deck and lip automatically return to stored position, protected by the dock bumpers, if the truck leaves the loading dock.

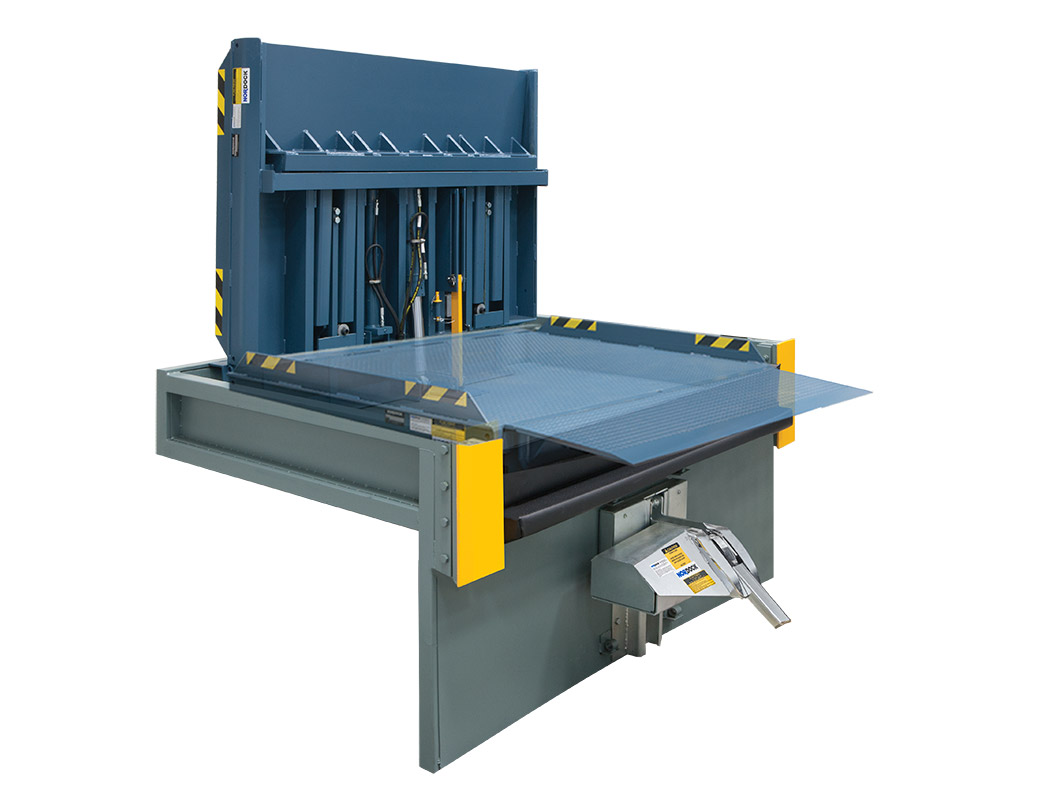

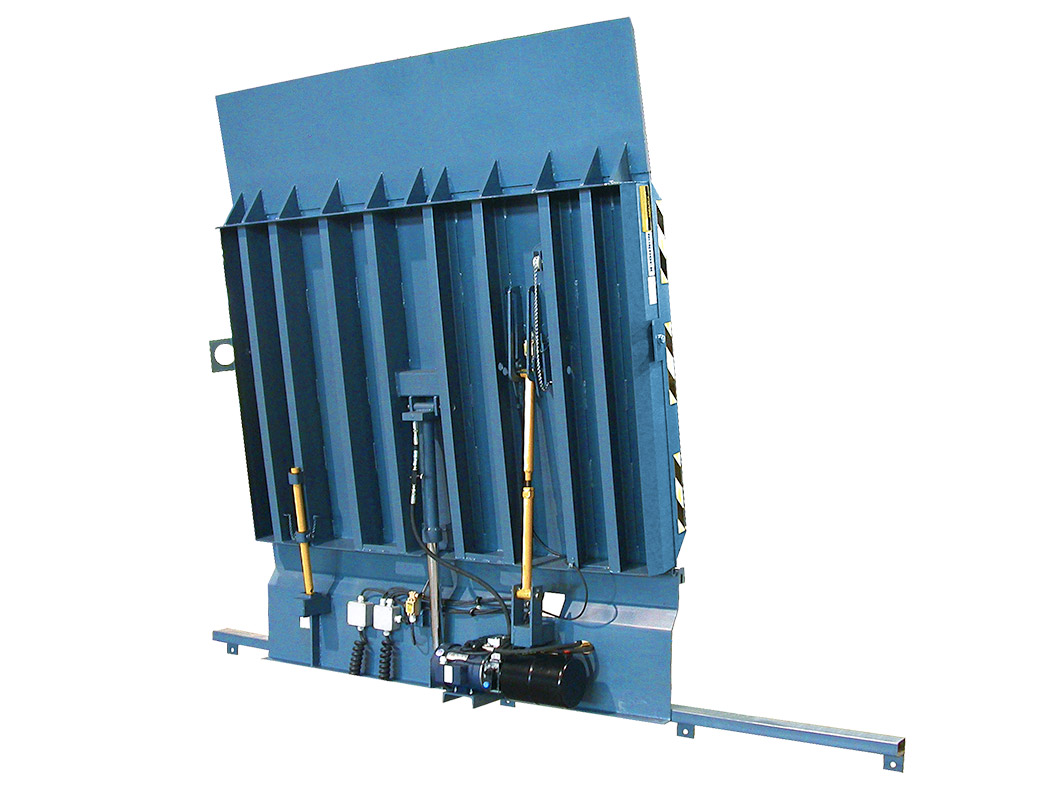

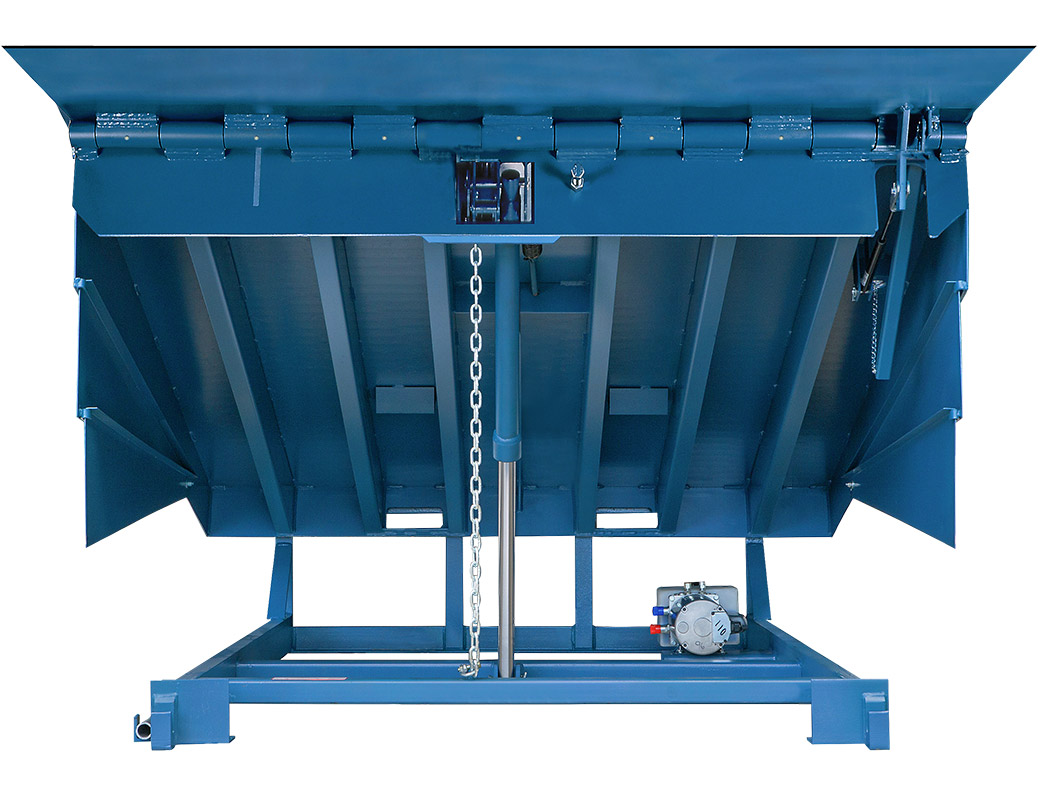

CONSTRUCTION

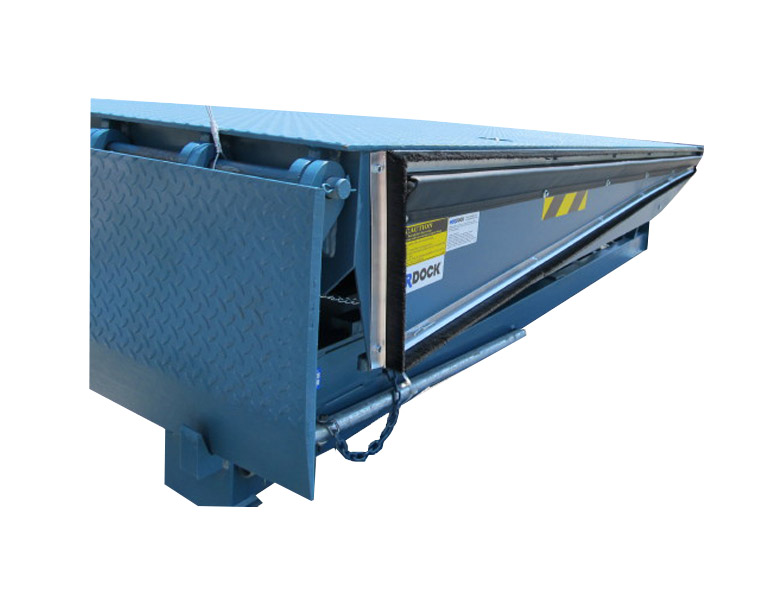

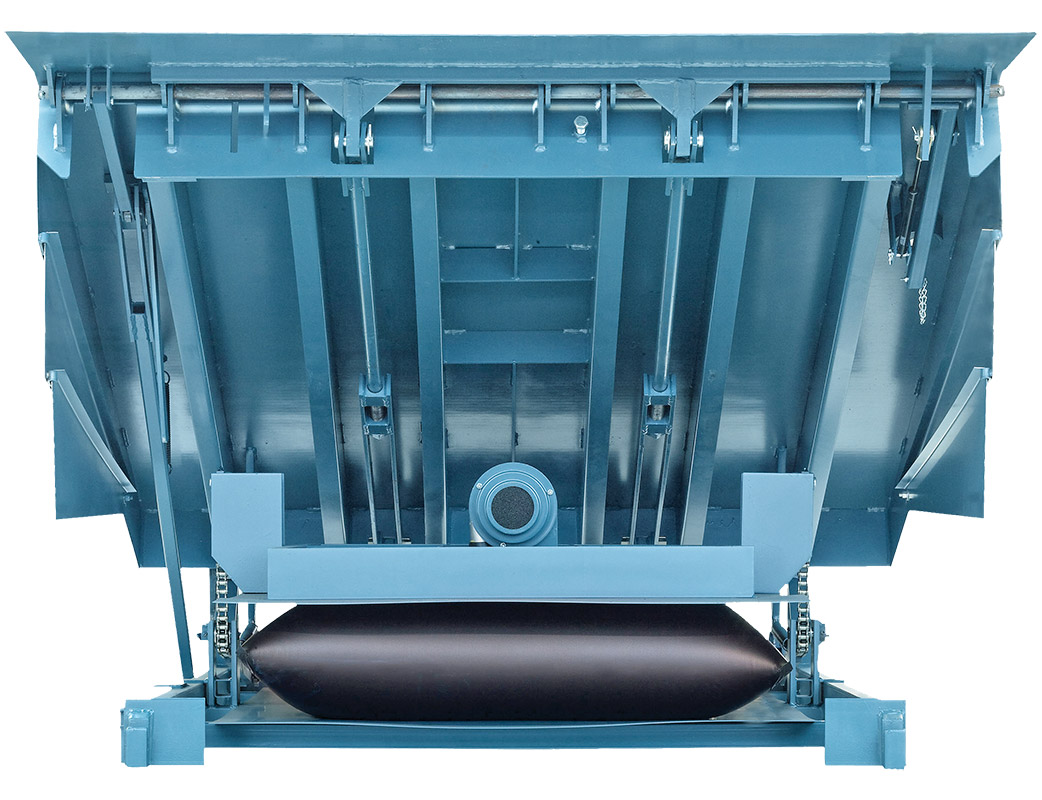

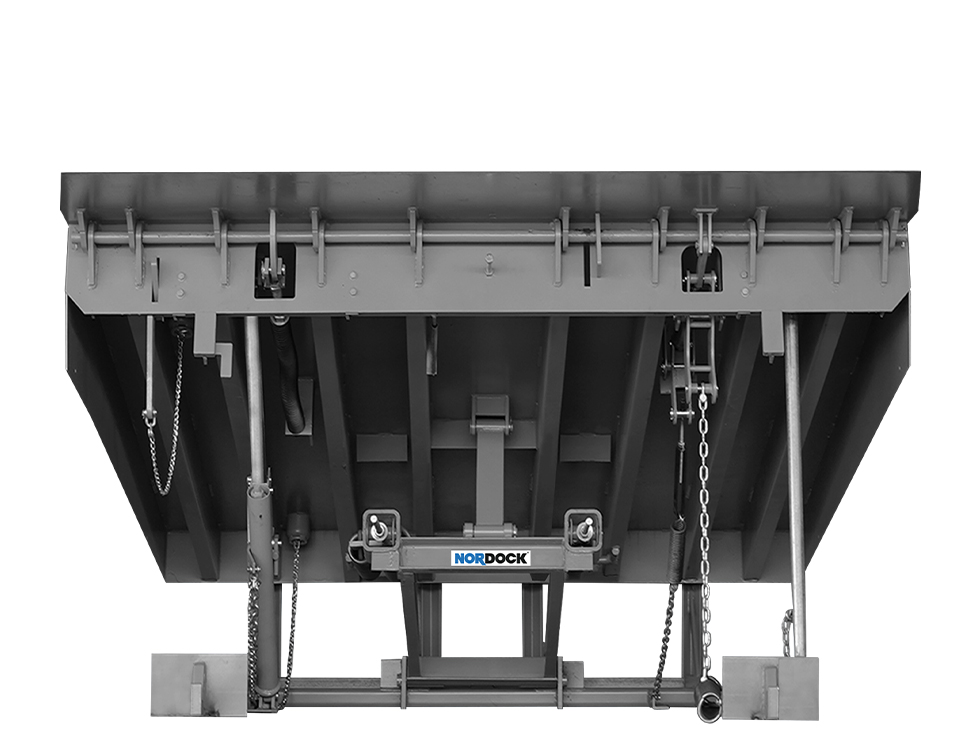

The 19” high frame has six solid steel rear supports, an open design for easy pit cleaning, and lip supports that prevent illegal entry when the door is closed.

The front and rear hinge rods are SAE 1045 superior shaft, zinc coated with factory applied anti-seize lubricant. Steel tread plate deck, lip, and lip lugs to be constructed of Minimum 55,000-PSI yield material. Ramp to be continuously welded to the deck lugs and rear piano hinge. The lip to be full width of plate, non-tapered with leading edge chamfer milled at maximum 15 degrees.

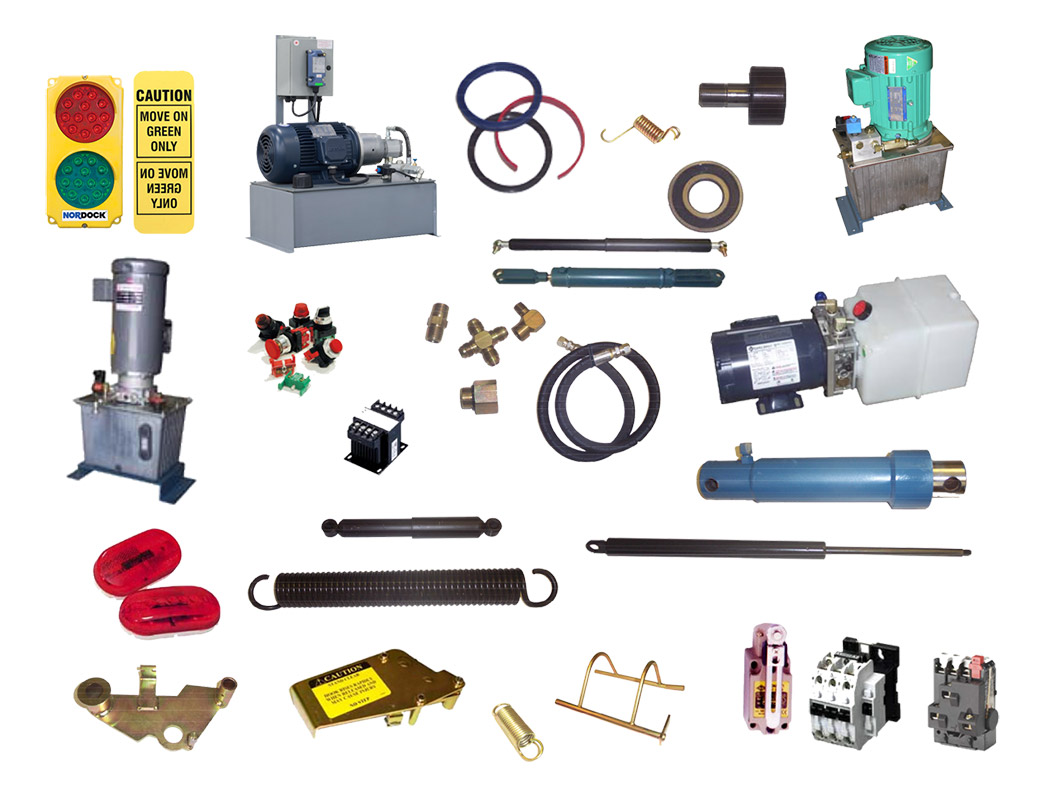

Welded sub-frame assembly with full width rear hinge and solid steel deck supports. Bumper extension blocks to be closed on all sides with a 4” projection bumper attached for a total projection of 18” from foundation wall. The power unit is a 1 HP integral assembly factory mounted and tested. Heavy-duty hydraulic cylinders are designed with polished chrome rod, seamless tubing, and high-pressure seals. Wall mounted control panel provided with single push button.

WARRANTY

NORDOCK® guarantees that the EH PUSH-BUTTON™ series of hydraulic edge of dock levelers will perform as described and to the full satisfaction of the purchaser for one-year from date of receipt or NORDOCK® will repair, replace or remove the product and refund the purchase price.