FEATURES & BENEFITS

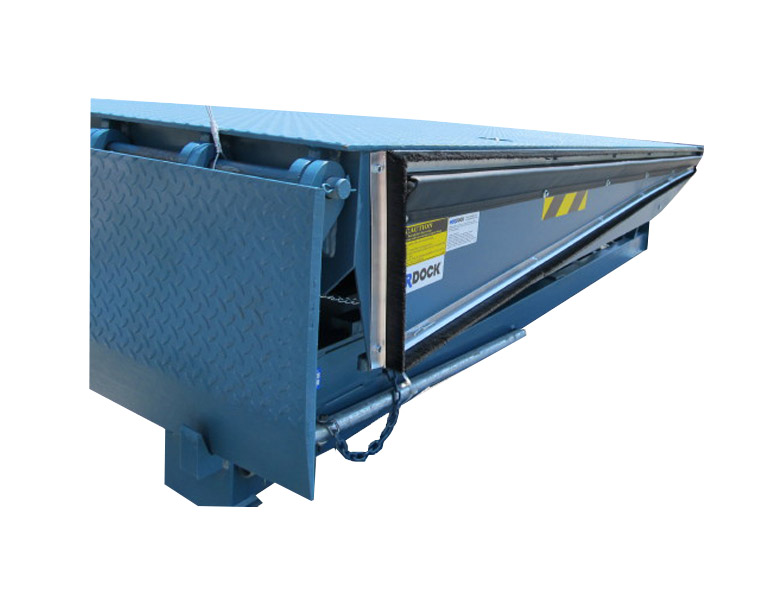

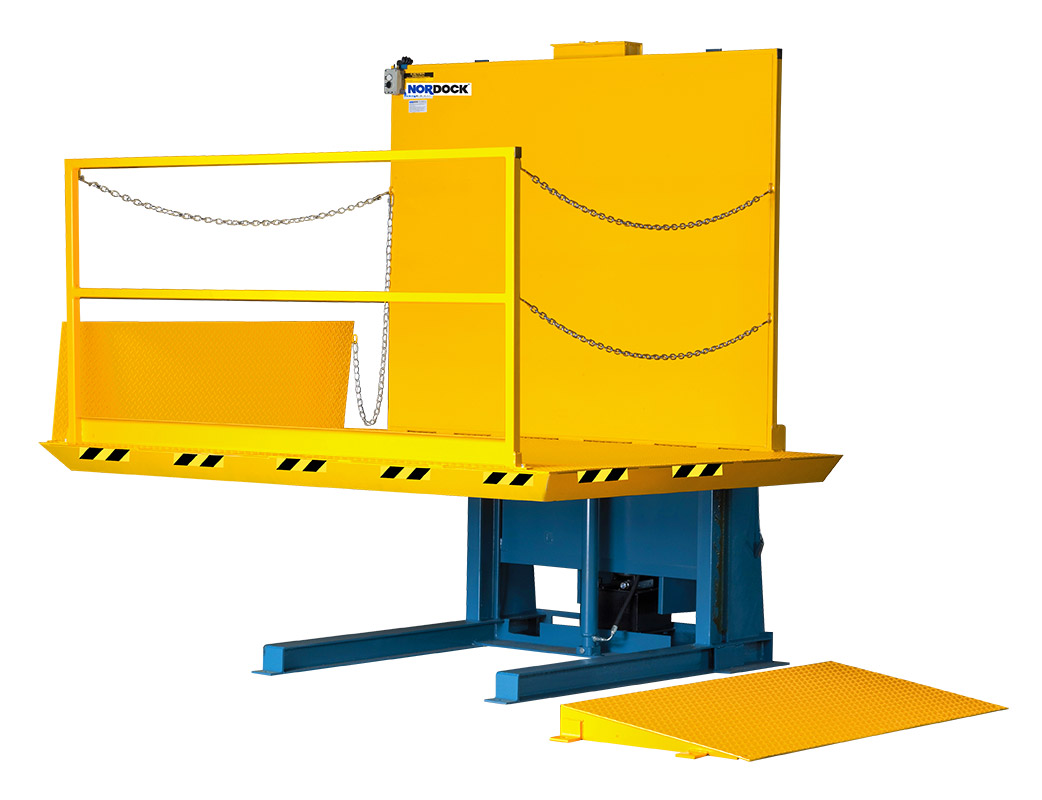

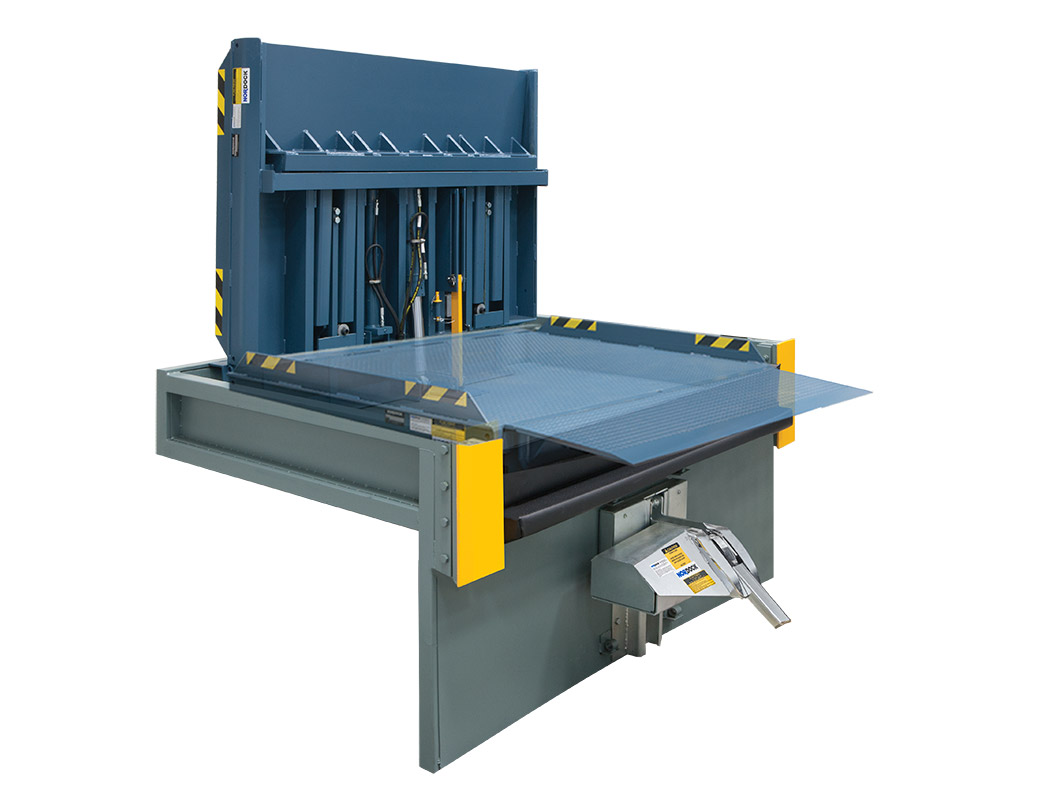

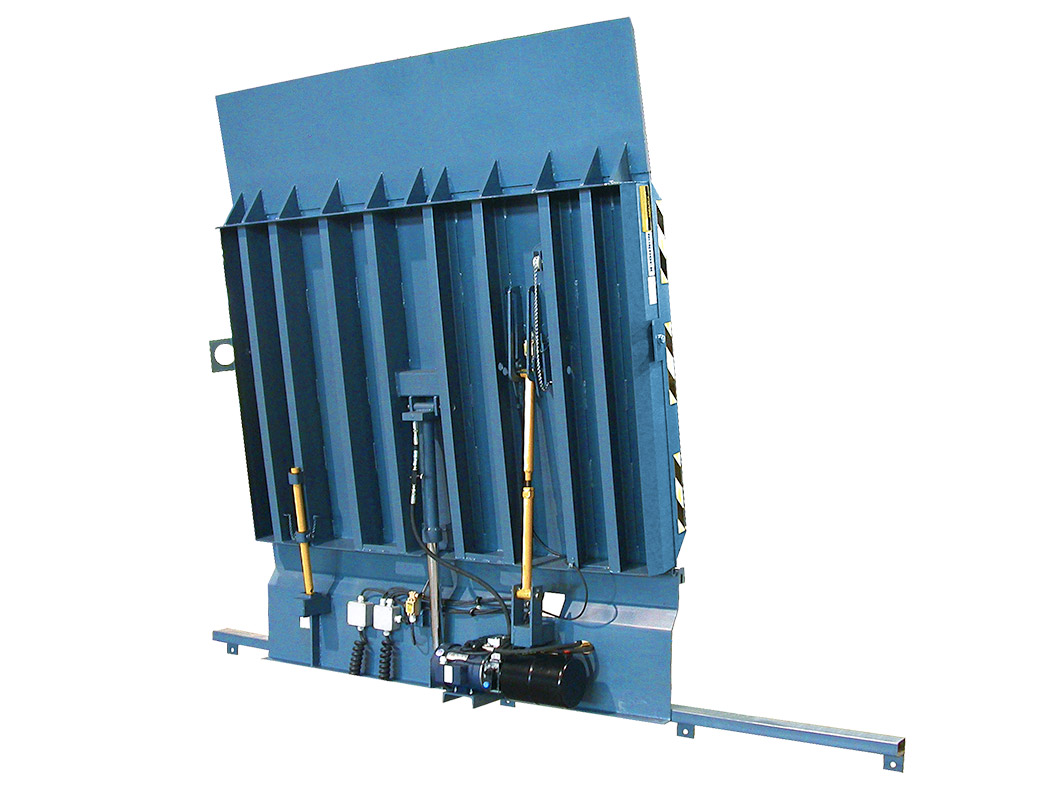

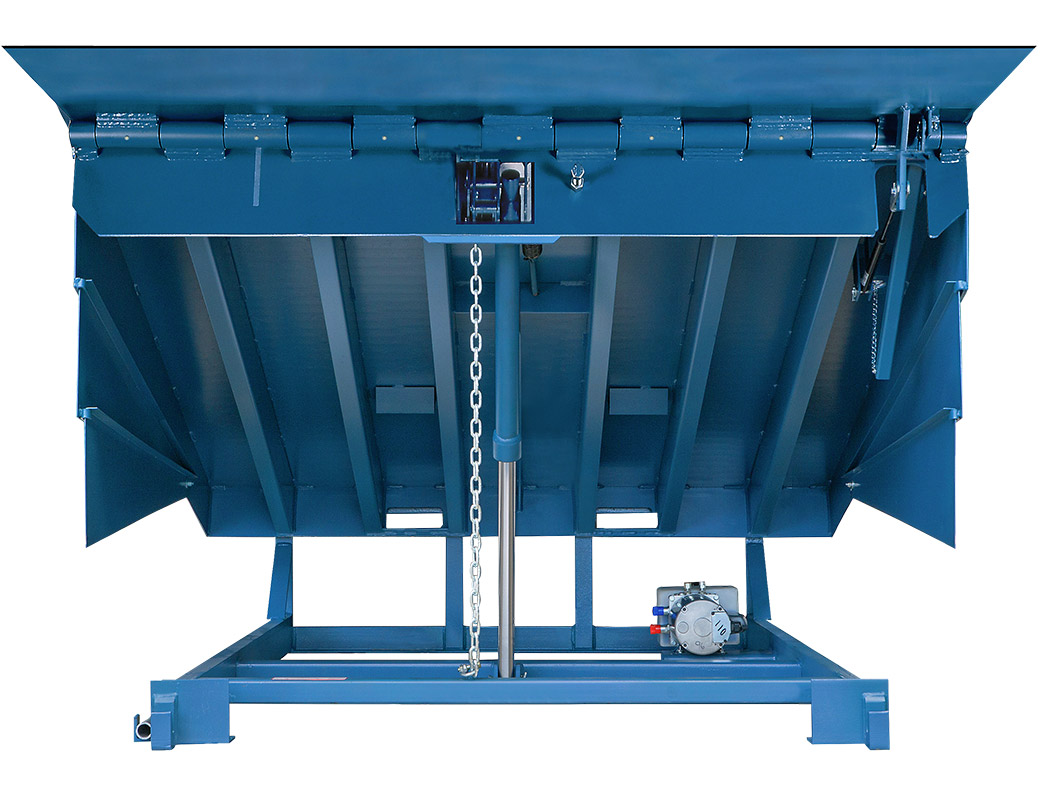

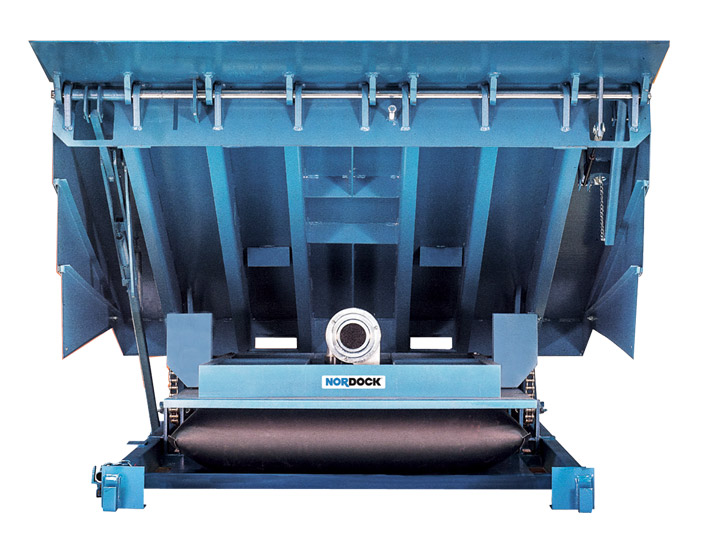

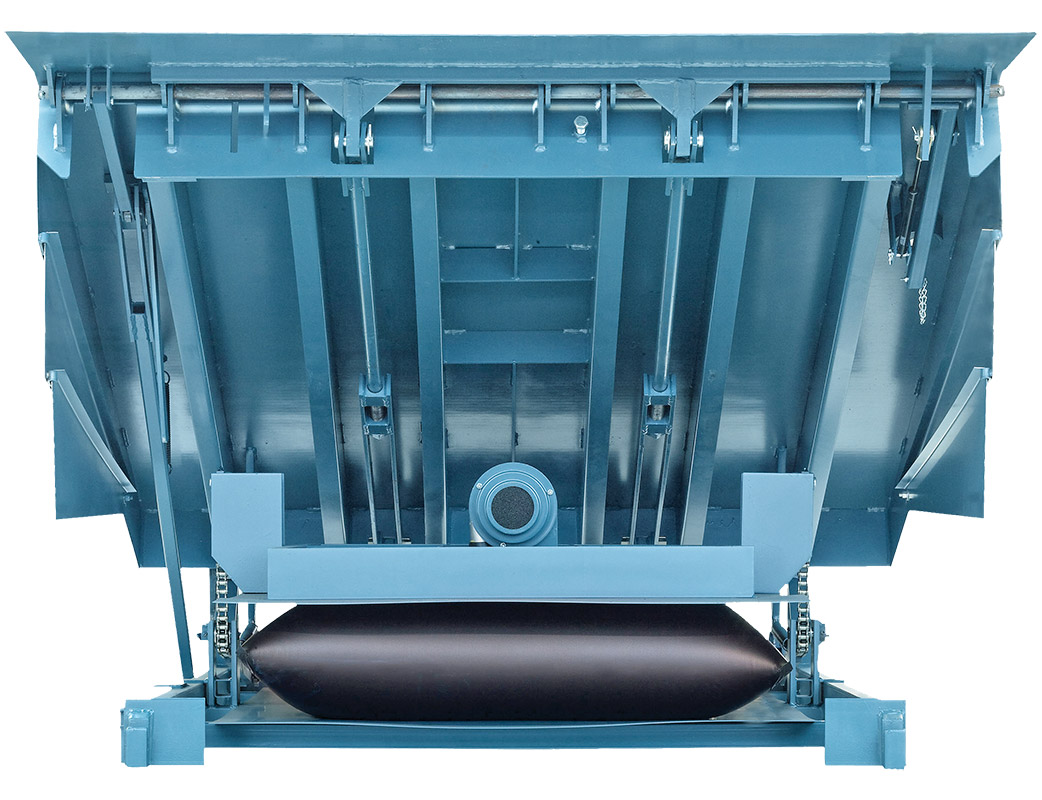

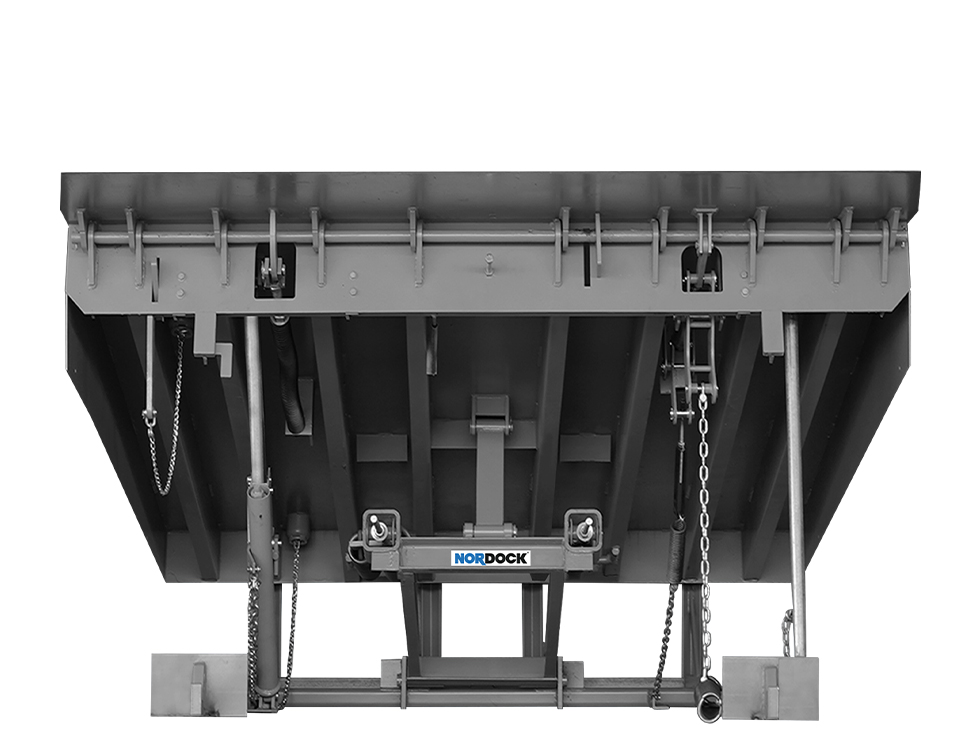

- Retrofit Capability Available to Fit into Existing Docks without Recutting the Pit

- TELESCOPING-LIP™ Eliminates End Load Issues with Precise Lip Control, Avoiding Cargo Damage Forever

- Continuous Fixed Rear Hinge Provides Smooth Transfer with No Pinch Point

- Flush Storing Improves Sight lines and Increases Floor Space for Safe Cross Traffic Operation and Staging Area

- Reduces Energy Loss & Dock Contamination

- No Run-Off Guards Eliminate Impact and Damage to Forklift Tires and Improves Maneuvering

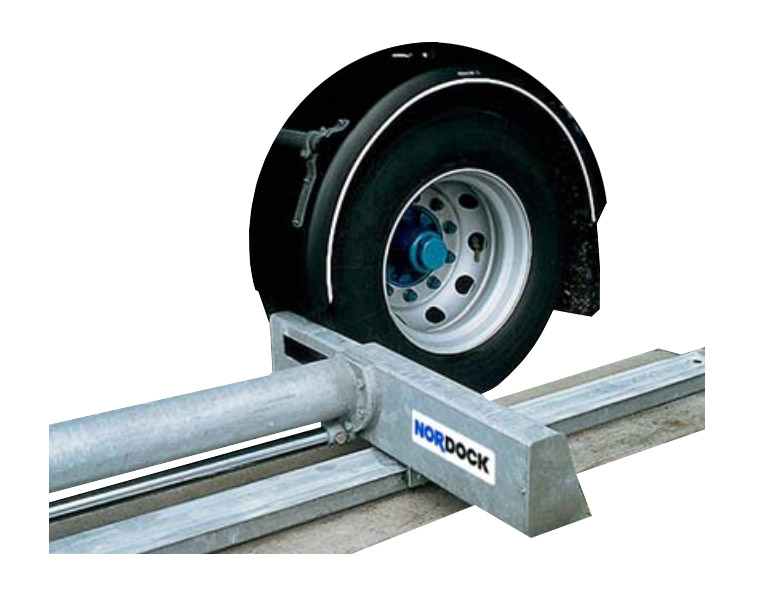

- Eliminates “Stuck Truck” – Forklift becoming Stuck between Trailer Bed and Loading Dock

- Eliminates Costly Installation of Bollards, Stanchions and Guardrails

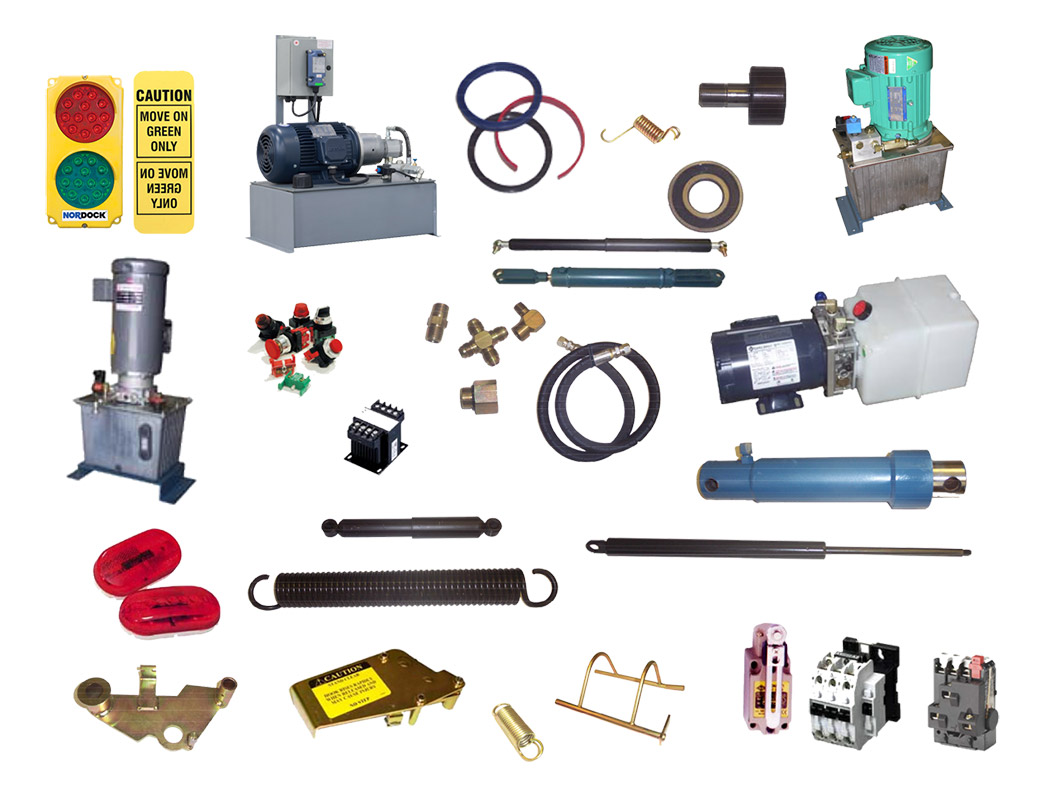

- NEMA 12 Control Panel Enclosure with Operator Instructions Printed on Cover

- 20” High Laminated Dock Bumpers Included

Miten Kasinord tutkii nettikasinoiden kehitystä Suomessa

Suomen rahapelimarkkinat ovat kokeneet merkittäviä muutoksia viime vuosikymmeninä, erityisesti digitalisaation myötä. Nettikasinoiden kehitys on ollut nopeaa ja monimuotoista, mikä on herättänyt kiinnostusta sekä pelaajien että alan asiantuntijoiden keskuudessa. Kasinord on vakiinnuttanut asemansa yhtenä johtavista toimijoista, joka seuraa ja analysoi näitä kehityssuuntia perusteellisesti. Ymmärtääksemme nykyistä tilannetta, on tärkeää tarkastella historiallisia vaiheita ja niiden vaikutuksia markkinoiden muotoutumiseen.

Nettikasinoiden historiallinen kehitys Suomessa

Suomen rahapelimarkkinoiden historia ulottuu 1920-luvulle, jolloin Veikkaus perustettiin. Pitkään markkinat olivat tiukasti säänneltyjä ja valtion monopolin alaisuudessa. Internetin yleistyminen 1990-luvulla toi mukanaan uusia mahdollisuuksia, mutta myös haasteita perinteiselle monopolijärjestelmälle.

Ensimmäiset nettikasinot saapuivat Suomeen 2000-luvun alussa, vaikka ne toimivat ulkomaisilla luvilla. Tämä aiheutti kiivasta keskustelua lainsäädännön riittävyydestä ja kuluttajansuojasta. Vuonna 2001 Veikkaus lanseerasi ensimmäisen virallisen nettipelisivustonsa, mikä merkitsi käännekohtaa suomalaisessa rahapelitoiminnassa.

2010-luvulla kehitys kiihtyi huomattavasti. Mobiiliteknologian kehittyminen mahdollisti pelaamisen missä tahansa ja milloin tahansa. Samaan aikaan ulkomaisten toimijoiden määrä kasvoi räjähdysmäisesti, mikä loi paineita kansallisen lainsäädännön uudistamiselle. Vuonna 2017 toteutettu rahapelilain uudistus pyrki vastaamaan näihin haasteisiin.

Kasinordin tutkimusmenetelmät ja analyysityökalut

Kasinord hyödyntää monipuolisia tutkimusmenetelmiä nettikasinoiden kehityksen seuraamisessa. Kvantitatiivinen data kerätään systemaattisesti eri lähteistä, mukaan lukien pelaajatilastot, markkinaosuudet ja teknologiset innovaatiot. Kvalitatiivinen tutkimus puolestaan keskittyy pelaajien käyttäytymisen ja mieltymysten analysointiin.

Yksi keskeisistä työkaluista on markkina-analyysi, joka tarkastelee toimijoiden määrää, niiden tarjoamia palveluja ja kilpailutilannetta. Kasinord dokumentoi säännöllisesti uusien pelityyppien ilmaantumista ja teknologisten ratkaisujen käyttöönottoa. Erityistä huomiota kiinnitetään mobiilipelaamisen kehitykseen, joka on muokannut merkittävästi pelaajien tapoja.

Tutkimuksessa hyödynnetään myös kansainvälistä vertailua. Suomen markkinoita verrataan muihin Pohjoismaihin ja EU-maihin, mikä antaa perspektiiviä kansallisiin kehityssuuntiin. Tämä vertaileva analyysi auttaa ymmärtämään, mitkä tekijät vaikuttavat markkinoiden muotoutumiseen eri maissa.

Teknologinen kehitys on ollut merkittävä tutkimuskohde. Kasinord seuraa esimerkiksi live-pelien yleistymistä, virtuaalitodellisuuden mahdollisuuksia ja tekoälyn hyödyntämistä pelitarjonnassa. Nämä innovaatiot vaikuttavat suoraan pelaajien kokemuksiin ja markkinoiden kehitykseen.

Nykyiset trendit ja markkinadynamiikka

Tämänhetkinen nettikasinoiden kehitys Suomessa määrittyy useista keskeisistä trendeistä. Mobiilipelaaminen on kasvanut hallitsevaksi tavaksi, ja https://kasinord.com/ on dokumentoinut, kuinka yli 70 prosenttia pelaamisesta tapahtuu nykyään mobiililaitteilla. Tämä on johtanut pelintarjoajien keskittymiseen käyttäjäystävällisiin mobiilisovelluksiin ja responsiiviseen web-suunnitteluun.

Pelitarjonta on monipuolistunut merkittävästi. Perinteiset kolikkopelit ovat saaneet seurakseen live-kasinopelit, joissa oikeat jakajat toimivat suorana videoyhteydessä. Urheiluvedonlyönti on integroitu yhä useammin kasinopalveluihin, luoden kokonaisvaltaisia viihdealustoja.

Vastuullinen pelaaminen on noussut keskeiseksi teemaksi. Kasinord on havainnut, että toimijat investoivat yhä enemmän työkaluihin, jotka auttavat pelaajia hallitsemaan pelaamistaan. Itsesulkumahdollisuudet, pelirajojen asettaminen ja reaaliaikainen pelaamisen seuranta ovat yleistyneet.

Kryptovaluuttojen käyttö maksutapana on herättänyt kiinnostusta, vaikka sääntelyepävarmuus hidastaa niiden yleistymistä. Samaan aikaan perinteiset maksutavat ovat nopeutuneet, ja välittömät kotiutukset ovat tulleet standardiksi.

Personointi on toinen merkittävä trendi. Tekoäly ja koneoppiminen mahdollistavat yksilöllisten pelikokemusten luomisen, jossa pelaajalle ehdotetaan hänen mieltymyksiään vastaavia pelejä ja bonuksia. Tämä kehitys on muuttanut markkinointia kohdennetummaksi ja tehokkaammaksi.

Sääntelyn vaikutus kehitykseen

Lainsäädännön muutokset ovat olleet merkittävä kehityksen ohjaaja. Vuoden 2017 rahapelilain uudistus toi mukanaan tiukempia vaatimuksia mainostamiselle ja pelaajien suojaamiselle. Kasinord on seurannut, kuinka nämä muutokset ovat vaikuttaneet toimijoiden strategioihin ja markkinoiden rakenteeseen.

Verotuksen kiristyminen on johtanut siihen, että osa ulkomaisista toimijoista on vetäytynyt Suomen markkinoilta. Toisaalta tämä on antanut tilaa uusille, säännösten mukaisesti toimiville yrityksille. Kuluttajansuojan parantaminen on ollut myönteinen kehityssuunta, vaikka se on lisännyt toimijoiden kustannuksia.

EU:n digitaalisten palvelujen säädökset vaikuttavat yhä enemmän kansalliseen lainsäädäntöön. Tämä luo haasteita, mutta myös mahdollisuuksia yhtenäisempien eurooppalaisten standardien kehittämiselle. Tietosuoja-asetuksen (GDPR) vaikutukset ovat olleet merkittäviä erityisesti asiakastietojen käsittelyssä.

Nettikasinoiden kehitys Suomessa jatkuu dynaamisena prosessina, jossa teknologiset innovaatiot, sääntelyn muutokset ja pelaajien mieltymykset muokkaavat jatkuvasti markkinoiden suuntaa. Kasinordin systemaattinen tutkimustyö tarjoaa arvokasta tietoa näiden muutosten ymmärtämiseksi ja tulevien kehityssuuntien ennakoimiseksi. Alan jatkuva kehittyminen edellyttää huolellista seurantaa ja analyysien päivittämistä, jotta voidaan tarjota ajantasaista ja luotettavaa tietoa kaikille markkinoiden toimijoille.