Deck Sizes & Capacities

Custom sizes and capacities are available.

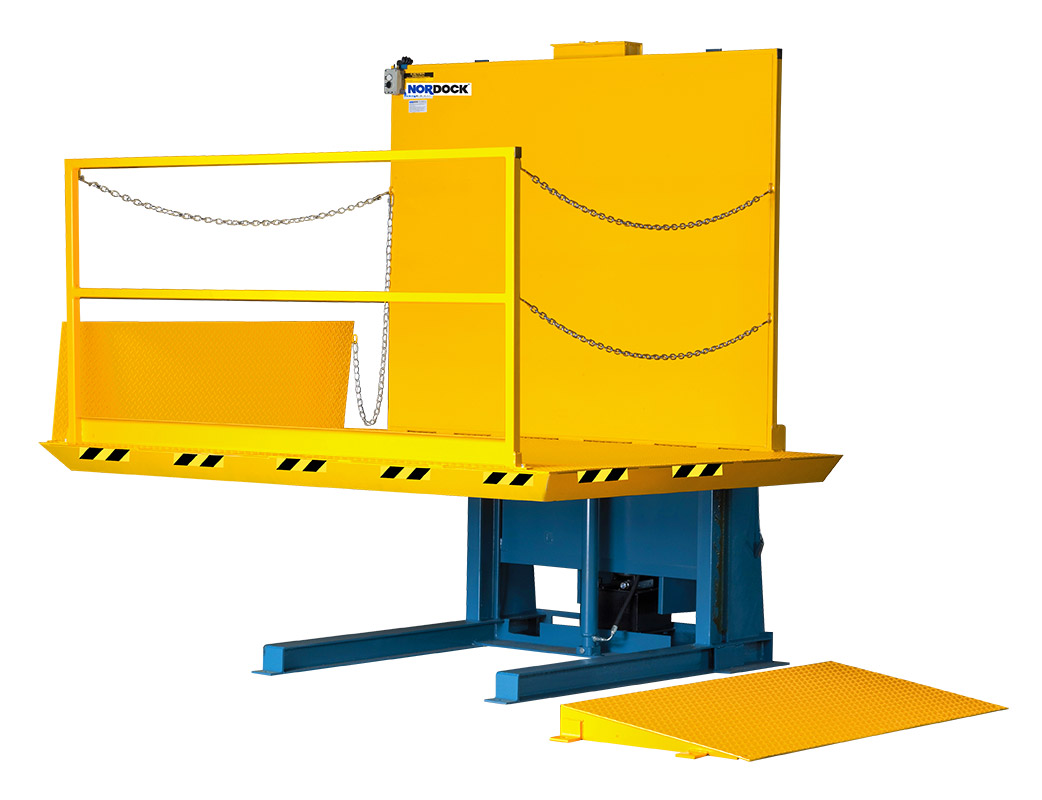

Operation

With the platform in its stored position the operator moves on to the platform and presses the raise button until the hinged bridge can be lowered on to the truck bed. Releasing the control button stops the platform movement. The operator can ‘inch’ the platform into position using the raise and lower buttons to ensure the bridge and platform are level with the truck bed.

The operator then moves goods in and out of the truck.

To return the lift to its stored position the operator, raises the bridge to its upright position and presses the lower button until the platform is at rest level with the floor.

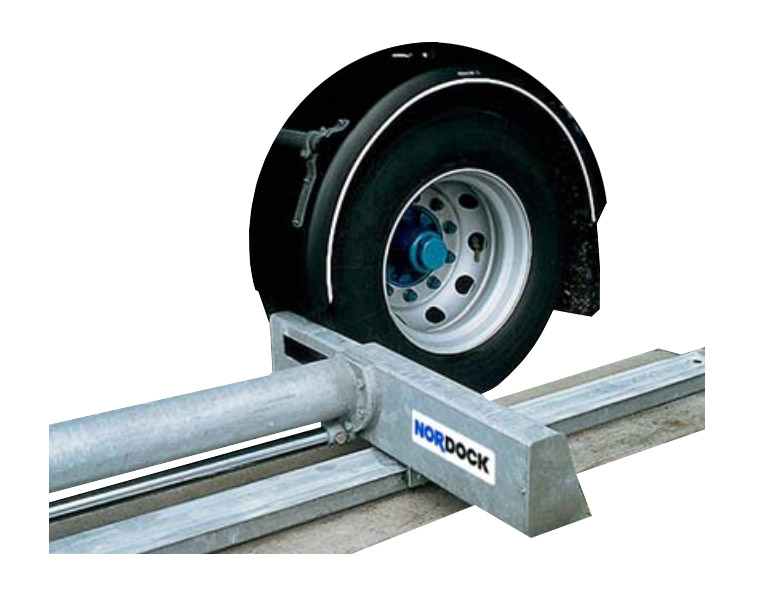

The barrier chains are always kept across the open ends of the handrails other than when the platform is stopped. The standard 18″ long bridge should project at least 10″ beyond the bumpers or bollards. Vertical service range is to 60″ above floor. Lowered height varies with style and capacity.

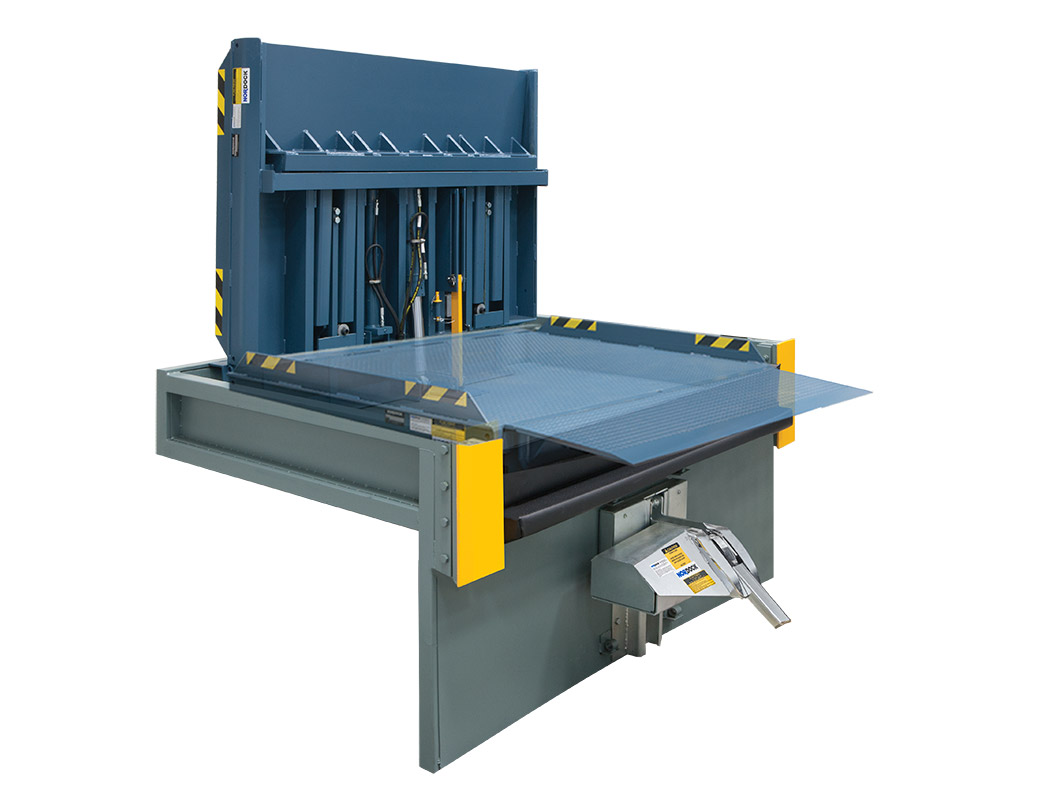

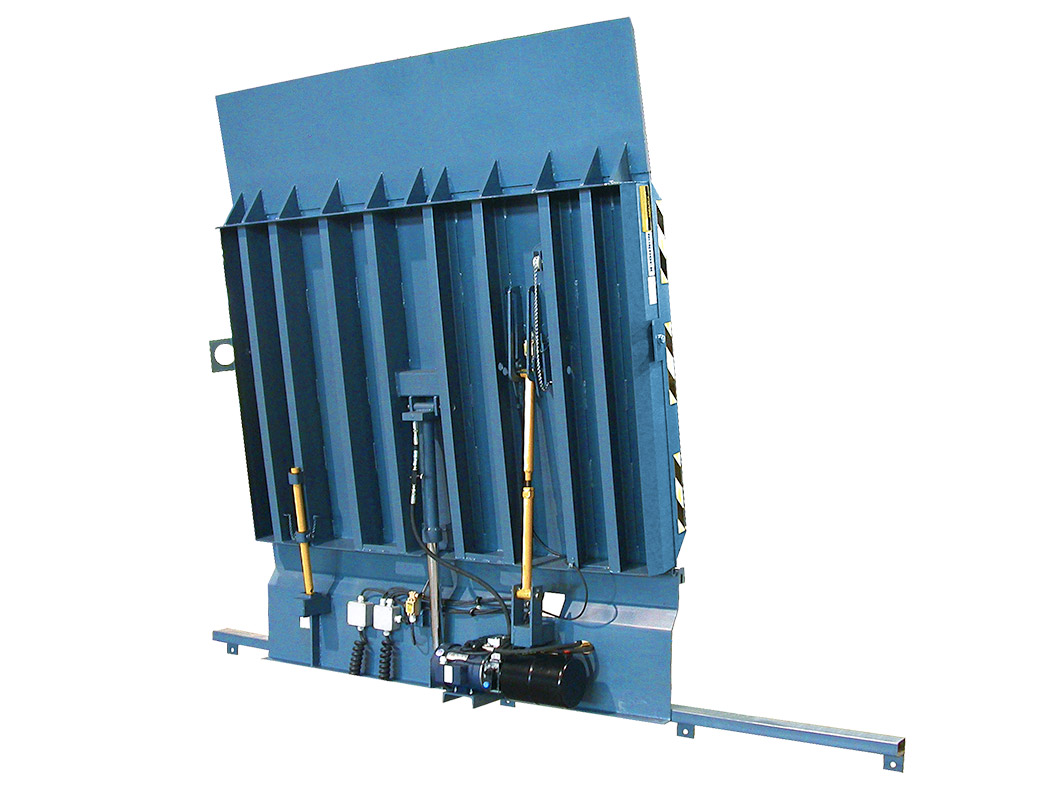

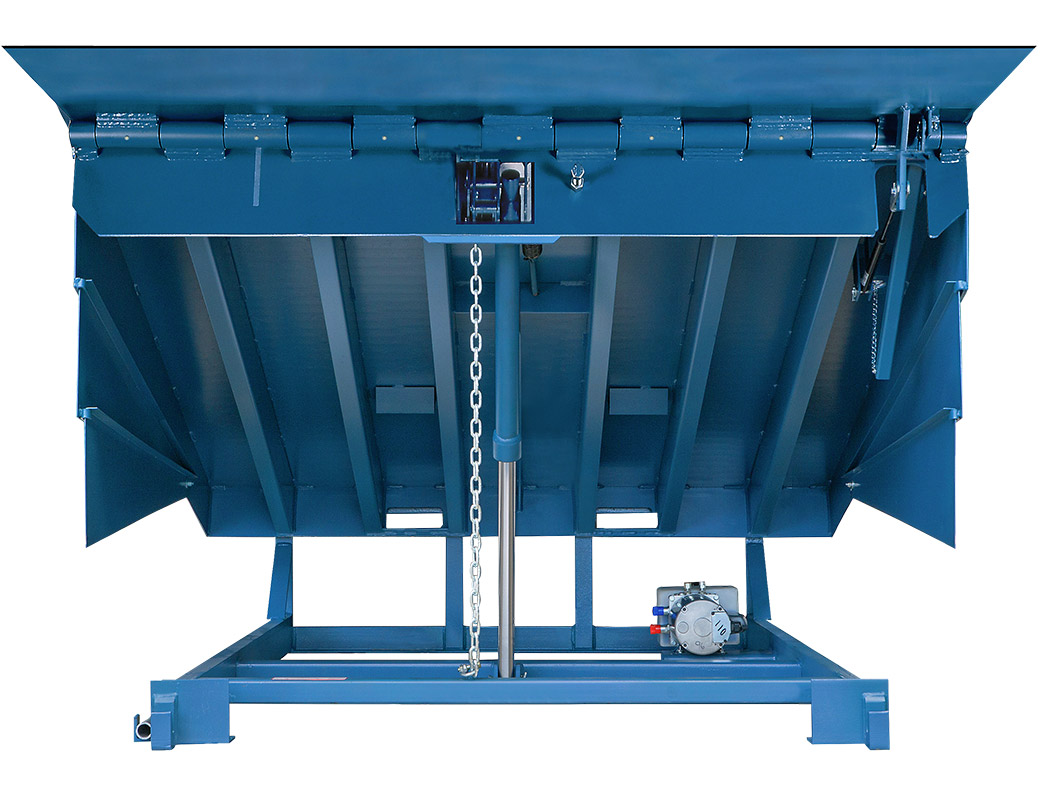

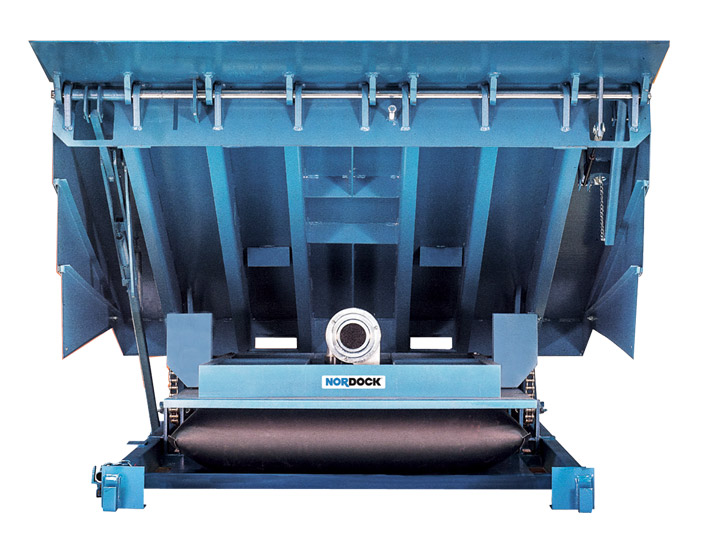

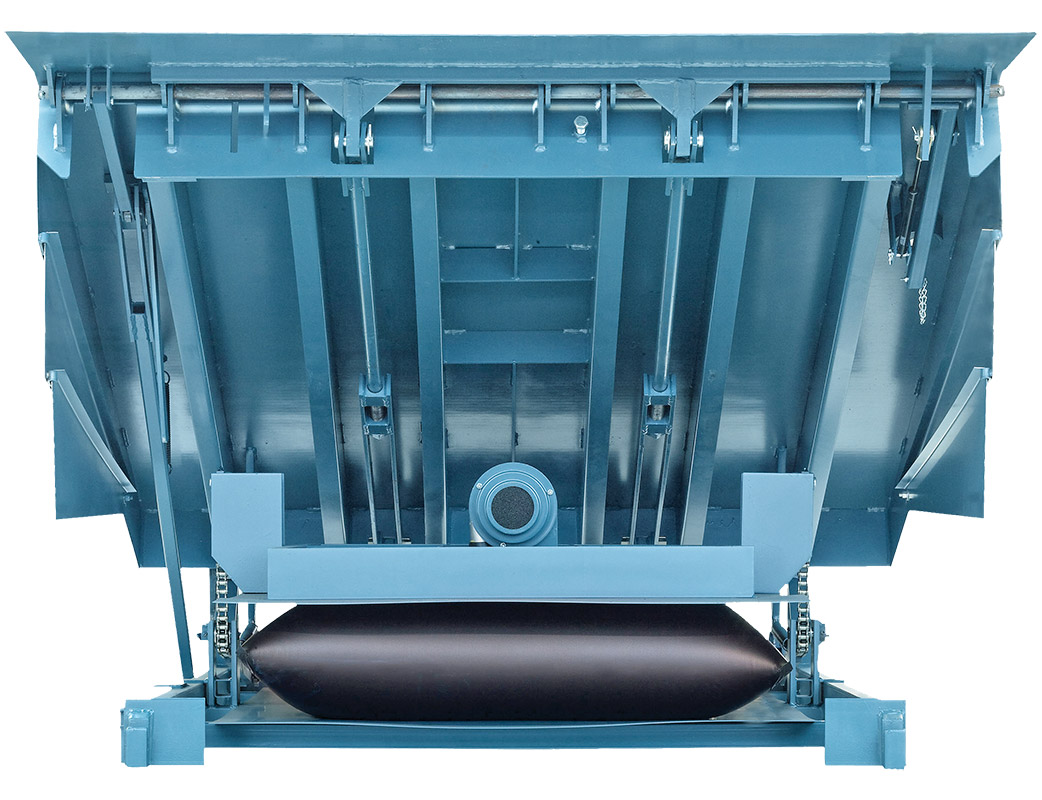

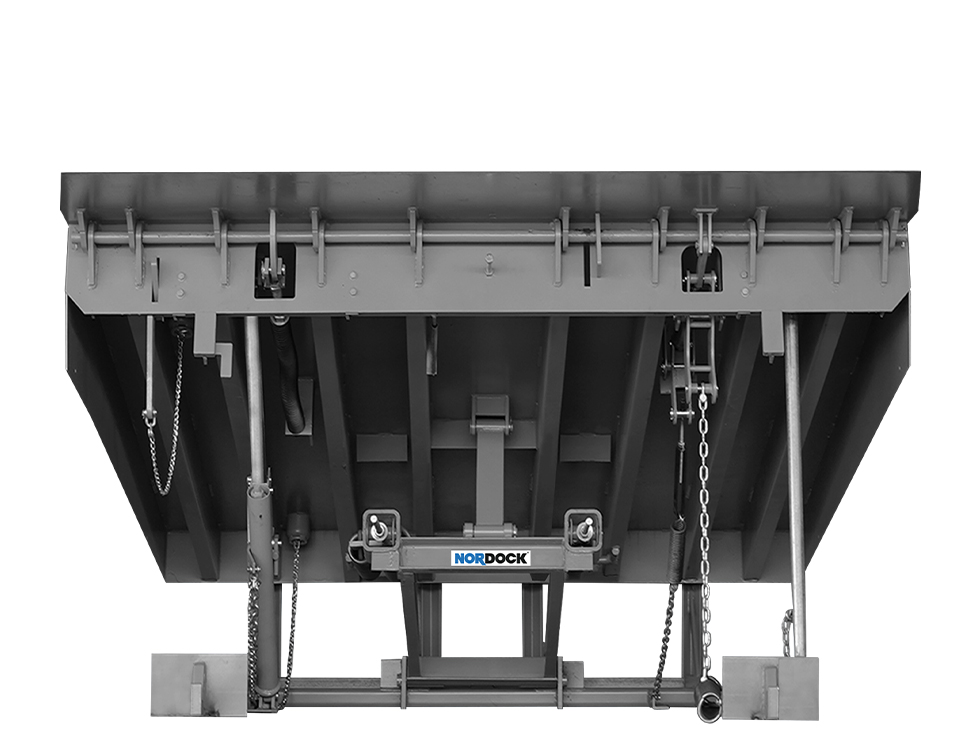

Construction

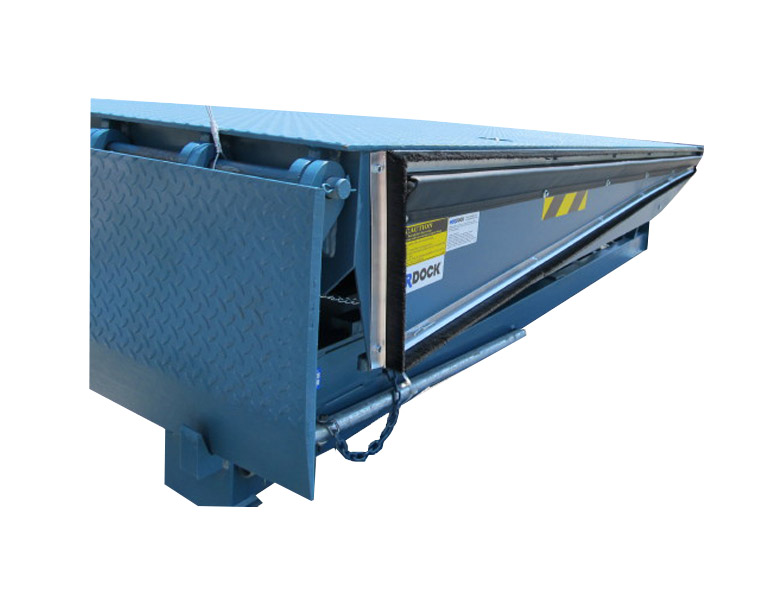

The platform is a unitized welded structure that is guided on a high tensile mast assembly with 8 sealed bearings for excellent stability. The platform, bridge and ramp are constructed with a non-slip checker plate surface. Each mast side of the platform is closed with a 60″ high solid panel with a 42″ high handrail provided on the opposite side.

Zinc plated restraint chains with snap releases close off the open ends of the platform.

A hinged bridge with lifting chain is provided to access the truck and a hinged or stationary ramp to access the floor. Maintenance pins are provided to support the empty lift in a raised position.

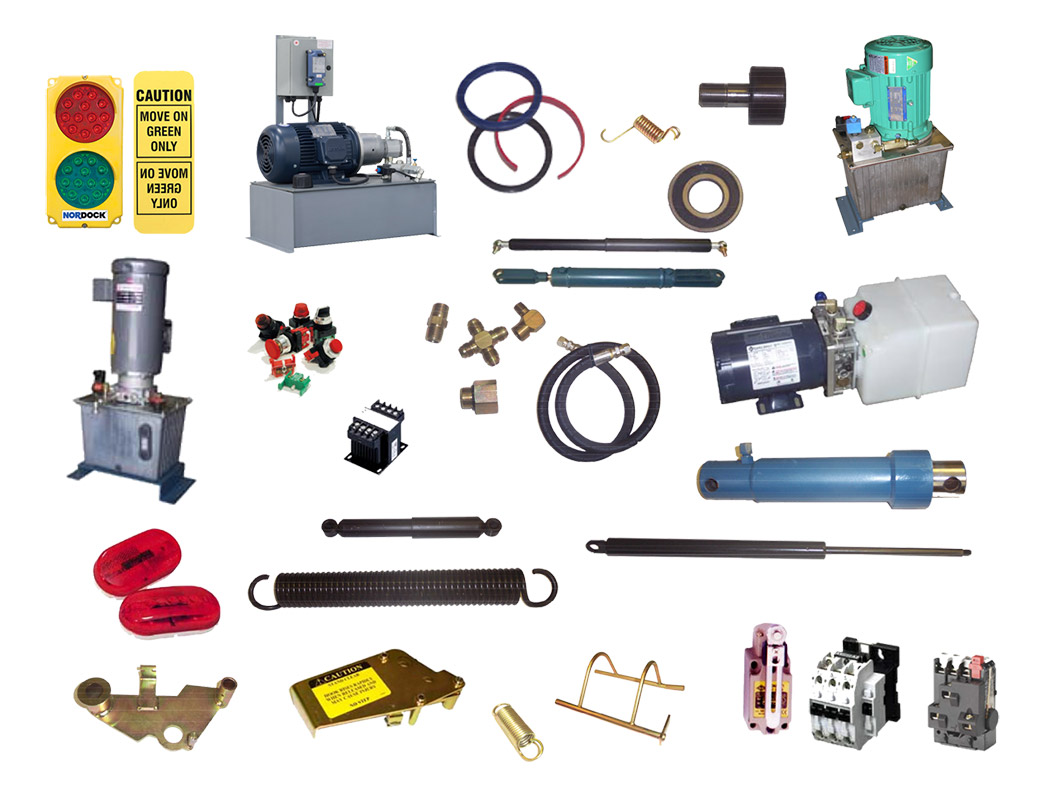

Electrical/Hydraulics

The power unit assembly includes a 3 Phase TEFC motor, gear pump, valve manifold, filters and an oil filled reservoir. The control panel includes a NEMA 12 enclosure with motor starter, thermal overload, and reduced voltage transformer. The push button control is a NEMA 4 weatherproof type attached to a retractable cord or mounted on the side panel. The hydraulic cylinders are of a heavy-duty design with polished chrome rod, guide bearing, spherical bearing, and high-pressure low-friction seals.

Velocity fuses are installed that will arrest the descent of the lift if the oil pressure is interrupted. The hydraulic hoses are SAE 100R2 high pressure with permanent fittings attached.

Warranty

NORDOCK® guarantees that the MAST-GUIDE™ Series of hydraulic platform lifts will perform as described for One-Year from date of receipt.

In addition NORDOCK® guarantees, under specified guidelines, the structural components for Ten-Years, and the hydraulic components for Five-Years.